You probably see industrial fans everywhere in today’s factories, server rooms, and even farms. These cooling fans keep machines running smoothly by moving air and controlling heat. In 2025, industrial cooling fans play a key role in keeping workplaces safe, efficient, and productive.

- The global market for industrial cooling fans is projected to reach $7,568.9 million in 2025.

- Experts expect a steady growth rate of 4.8% from 2025 to 2030.

Here’s how these fans make a difference across industries:

| Application Area | Benefit Description |

|---|---|

| Manufacturing | Helps control heat from machines, preventing equipment failure and maintaining safe temperatures. |

| Agriculture | Enhances air quality and temperature control, improving conditions for livestock and crop production. |

| Data Centers | Moves hot air out and cool air in, ensuring optimal operating conditions for servers and equipment. |

| Food Processing | Facilitates faster drying processes, increasing efficiency in production. |

| Power Plants | Keeps turbines cool, preventing overheating and maintaining efficiency. |

| Mining and Tunneling | Provides fresh air circulation, ensuring safety in underground environments. |

| Refrigeration | Distributes cold air evenly in storage units, preventing warm spots and preserving product quality. |

If you want to know How Do Cooling Fans Work or why they matter for your business, you’re in the right place.

Key Takeaways

- Industrial cooling fans are essential for maintaining safe temperatures and air quality in factories, data centers, and farms.

- Advanced EC and DC fans offer smart controls and energy savings, making them a smart choice for modern industrial applications.

- Proper airflow management prevents equipment overheating, enhances productivity, and improves workplace safety.

- Investing in energy-efficient fans can significantly reduce electricity costs and support sustainability goals.

- Industrial fans are versatile, with applications in manufacturing, HVAC, food processing, and more, ensuring reliable performance across industries.

What Are Industrial Fans?

Definition and Main Function

When you step into a factory or a large warehouse, you notice the powerful airflow right away. That’s the work of industrial fans. These machines are much bigger and stronger than the fans you use at home. You rely on industrial fans to move air across huge spaces, keeping equipment cool and air clean.

- Industrial fans are large-scale air-moving devices designed for tough environments.

- They operate continuously under high loads and withstand heat, dust, and vibration.

- You find different types, like axial fans, centrifugal fans, and mixed-flow fans. Each type fits specific industrial needs.

- The main functions include cooling machinery, ventilating hazardous fumes, and controlling indoor climate.

Industrial fans stand out from regular fans because of their design and performance. Here’s a quick comparison:

| Feature | Industrial Fans | Standard Fans |

|---|---|---|

| Design | Larger, robust, made from durable materials | Smaller, lighter, often made from plastic |

| Airflow Capacity | High airflow, capable of moving large volumes of air | Lower airflow, suitable for smaller spaces |

| Power and Speed | More powerful motors, higher speeds | Less powerful motors, lower speeds |

| Durability | Heavy-duty, resistant to harsh conditions | Not designed for extreme environments |

| Noise Level | Typically noisier, acceptable in industrial settings | Quieter operation, suitable for residential areas |

| Safety Features | Enhanced safety features for industrial use | Basic safety features |

You use industrial fans to keep machines from overheating. They help regulate temperature and prevent equipment failure. These fans also circulate air, which stops dust and fumes from building up. That means a safer and healthier workspace for everyone.

Note: fanacdc, powered by LINKWELL, leads the way in industrial cooling solutions. You get advanced fans designed for high performance, energy efficiency, and reliability. Their products fit the latest industrial requirements and offer smart control features for modern applications.

Where Industrial Fans Are Used

You see industrial fans in almost every major industry. Their applications go far beyond simple cooling. Here’s where you’ll find them working hard:

- Manufacturing: Cooling machinery and ventilating workspaces.

- Power Generation: Cooling turbines and generators.

- Chemical Processing: Ventilating hazardous gases and managing heat.

- Food & Beverage: Controlled airflow for drying and cooling.

- Pulp & Paper: Assisting in drying processes and odor control.

Let’s look at some specific industries and how they use industrial fans:

| Industry | Application Description |

|---|---|

| Asphalt & Cement | High-temperature airflow and dust control, ensuring compliance with air quality standards. |

| Chemical Processing | Managing heat and hazardous fumes, ventilating production areas, and integrating with air filtration systems. |

| Food Processing | Maintaining sanitation, regulating temperature, and preventing contamination in production areas. |

| Power Generation | Cooling critical components, managing emissions, and optimizing combustion efficiency. |

You depend on industrial fans for ventilation, cooling, drying, exhaust, and process control. These fans keep air moving, remove pollutants, and help maintain safe temperatures. In every industrial setting, they play a vital role in protecting both equipment and people.

How Do Cooling Fans Work?

You might wonder how do cooling fans work in massive factories or busy server rooms. The answer is simpler than you think. These fans use smart engineering to move air, control heat, and keep your equipment safe. Let’s break down the process so you can see what happens behind the scenes.

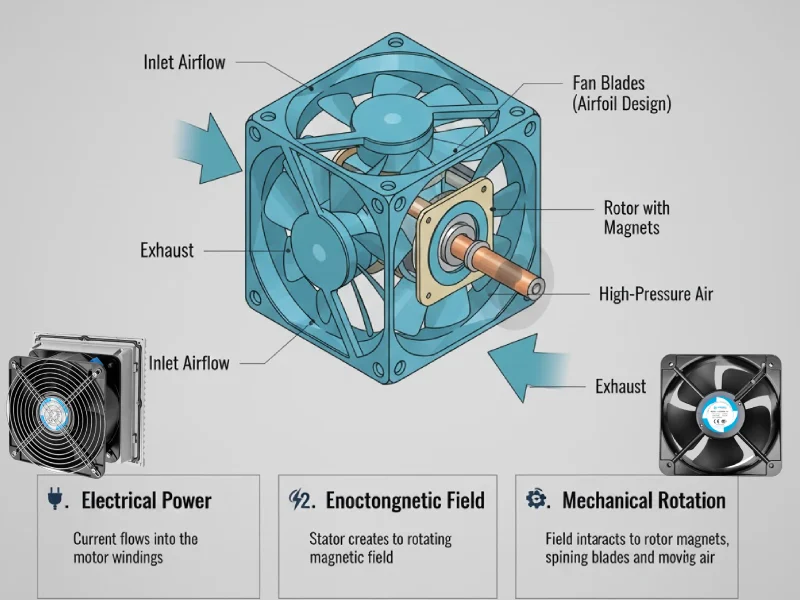

Operating Principles

When you switch on an industrial fan, you set a chain of actions in motion. The motor powers the impeller, which spins and pulls air into the fan. The blades push this air out, creating a steady flow that cools machinery and keeps the environment comfortable.

- Industrial cooling fans work by creating airflow that improves air circulation and comfort.

- They use convection and evaporative cooling principles. This means they help sweat evaporate faster from your skin, making the space feel cooler.

- High-volume low-speed fans don’t actually lower the air temperature. Instead, they move air efficiently, prevent hot spots, and distribute conditioned air throughout the area.

If you use EC fans from fanacdc, you get even more control. These fans combine AC and DC motor technology, so you can adjust speed and airflow with precision. DC fans also offer smart speed control, letting you fine-tune cooling for different needs. You can rely on these energy-efficient designs to keep your workspace safe and productive.

Tip: Smart fan controls let you adjust speed based on temperature. You save energy and keep your equipment running longer.

Key Components

Every industrial fan has several important parts that work together to keep things cool. Here’s what you’ll find inside:

- Impeller: This is the heart of the fan. The blades pull air in and push it out, creating the airflow you need for cooling machinery.

- Shaft and Bearings: These support the impeller and help it spin smoothly. If they wear out, your fan loses efficiency.

- Motor: The motor powers the impeller. You’ll see AC, DC, and EC motors in modern fans. EC motors, like those in fanacdc products, offer high efficiency and smart control.

- Fan Frame: This holds everything together and directs airflow where you need it most.

- Fan Accessories: Guards and filters keep your fan safe and clean, making sure it runs reliably.

Materials matter too. Take a look at how different materials affect durability and performance:

| Material | Strength and Durability | Resistance to Environmental Factors |

|---|---|---|

| Steel | High | Yes |

| Composite Materials | Moderate to High | Yes |

| Aluminum | Moderate | Yes |

| Copper | Moderate | Yes |

You want a fan built with strong materials. That way, it stands up to heat, dust, and vibration in tough industrial settings.

Heat and Airflow Management

How do cooling fans work to manage heat and airflow in large spaces? You’ll see these fans moving huge volumes of air across factories, warehouses, and data centers. This steady airflow keeps temperatures stable and prevents hot spots from forming.

Industrial cooling fans create gentle, uniform airflow. This helps your team stay comfortable and protects sensitive equipment from overheating. In winter, these fans mix warm air, reducing heat loss and saving energy.

Energy efficiency plays a big role in how do cooling fans work today. You get better thermal management, reliable system performance, and lower energy bills. Smart controls adjust fan speed based on temperature, saving up to 40% more energy than old fixed-speed models. Consistent cooling extends the life of your equipment and cuts down on maintenance costs.

- Cooling fans actively dissipate heat, preventing thermal fatigue and keeping machinery safe.

- Smart controls mean you only use as much energy as you need, making your operation more sustainable.

- Proper cooling boosts safety and reliability, especially in critical industries like manufacturing and electronics.

If you choose EC or DC fans from fanacdc, you get advanced technology that adapts to your needs. These fans offer precise airflow control, quiet operation, and long-lasting performance. You keep your workspace cool, your equipment safe, and your energy costs low.

Types of Industrial Fans in 2025

Axial and Centrifugal Fans

You see two main types of industrial fans in factories: axial and centrifugal. Axial fans move air straight through the fan, making them perfect for cooling large spaces with low resistance. Centrifugal fans push air out at a right angle, which helps when you need higher pressure or want to move air through ducts.

Here’s a quick look at how they compare:

| Feature | Axial Fans | Centrifugal Fans |

|---|---|---|

| Airflow Direction | Parallel to fan axis | 90-degree angle from intake |

| Air Volume | Large volumes, low pressure | Lower volume, higher pressure |

| Noise Level | Quieter | Louder |

| Power Requirement | Less power | More power |

| Common Uses | HVAC, server rooms, cooling towers | Ductwork, air conditioning, electronics |

You often find axial fans in server rooms, cooling towers, and agricultural buildings. Centrifugal fans work best in ducted systems or when you need to move air against resistance.

EC Fans by fanacdc

If you want smart control and energy savings, EC fans from fanacdc stand out. These fans use electronically commutated motors, blending AC and DC technology for high efficiency. You can adjust speed and airflow with precision, which helps you save energy in busy factories.

- EC fans cut power consumption by up to 50% compared to older models.

- They maintain high efficiency across a wide speed range.

- You get advanced control modes for constant pressure and stable operation.

EC fans from fanacdc help you optimize cooling and reduce costs. You can rely on their quiet operation and long service life.

DC Fans and Their Advantages

DC fans give you flexibility and reliability in industrial settings. You can control their speed with simple signals, which means you only use as much energy as you need. These fans run quietly and last longer because they use brushless motors.

- DC fans consume up to 70% less energy than AC fans.

- They work well in harsh environments, resisting dust and moisture.

- You can customize them for different applications in factories.

DC fans from fanacdc offer advanced features like PWM speed control and predictive maintenance. You get stable performance and less downtime.

Smart and Energy-Efficient Models

Smart industrial fans are changing how you manage air in factories. These models use IoT sensors to monitor temperature and humidity. They adjust airflow automatically, so you save energy and keep conditions safe.

| Feature | Description |

|---|---|

| Motor Technology | Brushless DC or EC motors for energy savings |

| Variable Speed Controls | Match airflow to real needs |

| Smart Features | Timers, sensors, automation integration |

| Energy Certifications | ENERGY STAR® and similar standards |

You can connect smart fans to building management systems. This lets you track performance and make changes in real time. You get better efficiency and lower energy bills.

Industrial Applications and Benefits

Manufacturing and Electronics

You see industrial fan technology everywhere in manufacturing and electronics. These fans keep machines cool and processes stable. When you run injection molding machines or operate reflow soldering ovens, you rely on cooling solution systems to manage excess heat. If you ignore temperature control, you risk damaging equipment and lowering product quality. Centrifugal fans provide strong airflow for cooling process air, materials, and exhaust streams. You get reliable performance and fewer shutdowns.

| Industry Sector | Applications |

|---|---|

| Manufacturing Equipment | Injection molding, extrusion, metal casting furnaces |

| Electronic Manufacturing | Reflow soldering, semiconductor fabrication, wave soldering machines |

| Food Processing Equipment | Industrial ovens, dehydrators, baking equipment |

| Automotive Manufacturing | Paint curing ovens, welding stations, heat treatment furnaces |

You benefit from industrial fans in many sectors, including chemical processing, glass manufacturing, and plastics. These practical applications of industrial fans help you maintain stable operations and protect sensitive electronics.

HVAC and Refrigeration

You depend on industrial fan systems to keep HVAC and refrigeration running smoothly. Fans regulate temperature by circulating air and preventing hotspots. If you use advanced EC fans from fanacdc, you get precise speed control and energy savings. These fans work with heat sinks, enclosures, and sensors to optimize cooling solution performance. You enjoy consistent comfort and lower energy bills.

- Fans maintain thermal equilibrium in HVAC and refrigeration.

- They help dissipate heat and improve energy efficiency.

- You get integrated thermal management for reliable operation.

Workplace Safety and Air Quality

You want a safe and healthy workspace. Industrial fans play a big role in air quality and safety. Exhaust fans remove dirty air, dust, and pollutants. Fresh air enters your facility, creating a pleasant atmosphere. Advanced fans keep air moving, eliminate stagnant zones, and clear hazardous substances. You notice fewer health issues and better concentration among your team.

- Fans lower perceived temperatures, making work more comfortable.

- Good air quality leads to fewer disruptions and higher productivity.

- Proper ventilation reduces respiratory risks and supports retention.

Energy Savings and Sustainability

You save energy and support sustainability goals with advanced industrial fan technology. EC fans from fanacdc can cut power consumption by up to 75% compared to older models. Electronically controlled brushless motors adjust speed based on demand, so you only use what you need. You reduce electricity costs and carbon emissions.

Tip: If you choose sustainable solutions like EC fans, you help your business meet environmental targets and create a greener workplace.

- Industrial fans control temperature and humidity, preventing spoilage and reducing energy use.

- They improve air quality, protecting worker health and reducing accidents.

- You boost energy efficiency and lower your carbon footprint.

You see the benefits of using industrial fans in every corner of your operation. These practical applications of industrial fans deliver reliable cooling, safer workplaces, and sustainable solutions for the future.

Conclusion

You’ve seen how industrial cooling fans shape the future of workplaces in 2025. These fans do more than just move air. They protect your equipment, keep your team safe, and help you save energy every day.

Let’s recap what you learned:

- Industrial cooling fans keep factories, data centers, and farms running smoothly.

- You rely on fans to control heat, improve air quality, and boost productivity.

- Advanced types like EC and DC fans from fanacdc offer smart controls, quiet operation, and big energy savings.

- You find these fans in manufacturing, electronics, HVAC, and more.

If you want reliable cooling and lower costs, you should look for energy-efficient solutions. EC and DC fans from fanacdc stand out because they combine smart technology with strong performance.

Here’s a quick table to help you remember the benefits:

| Feature | Why It Matters for You |

|---|---|

| Smart Controls | Adjust airflow for changing needs |

| Energy Efficiency | Cut down on electricity bills |

| Quiet Operation | Create a better work environment |

| Long Service Life | Reduce maintenance and downtime |

| Safety and Air Quality | Protect your team and equipment |

You can see that choosing the right fan makes a big difference. You get better cooling, safer spaces, and lower costs. Industrial fans will keep evolving, so you stay ahead with the latest technology.

Ready to upgrade your cooling system? Explore fanacdc’s EC and DC fans and power your business with innovation.

You’ve learned how industrial cooling fans keep your workplace safe and efficient. These fans help you control heat, improve air quality, and save energy. Advanced EC and DC fans from fanacdc give you smart controls and reliable performance. The market keeps growing, so you see more innovation and smarter designs every year.

| Key Aspect | Why It Matters in 2025 |

|---|---|

| Adoption | You benefit from advanced cooling in every industry |

| Investment | You see more funding for better materials and designs |

| Innovation | You get smarter fans with IoT and predictive maintenance |

FAQ

What makes EC fans from fanacdc energy efficient?

You get EC fans with advanced motor technology. These fans use smart controls to adjust speed and airflow. You save up to 75% on energy compared to traditional models.

Can you retrofit EC or DC fans into your existing system?

Yes, you can swap out old fans for EC or DC models. Just check the size, airflow direction, and mounting style. You upgrade your cooling without major changes.

How do you control the speed of industrial fans?

You use built-in smart features like PWM or analog control. These let you adjust fan speed based on temperature or system demand. You keep cooling efficient and quiet.

Are industrial cooling fans noisy?

You notice that advanced EC and DC fans run much quieter than older models. Brushless motors and aerodynamic blades help reduce noise, making your workspace more comfortable.

What maintenance do industrial fans need?

You spend less time on maintenance with brushless EC and DC fans. Just clean dust off the blades and check for unusual sounds. These fans are designed for long, trouble-free operation.