You might wonder what is a centrifugal fan and how it keeps your systems cool. A centrifugal fan moves air by spinning an impeller, pushing the air outward and changing its direction. This design lets centrifugal fans create high-pressure airflow for industrial spaces. If you need reliable cooling, fanacdc delivers trusted solutions with fans built for tough jobs. You can count on their fan to handle demanding environments and keep your equipment running smoothly.

Key Takeaways

- Centrifugal fans move air by spinning an impeller, creating high-pressure airflow ideal for cooling and ventilation.

- Key components like the impeller, motor, and housing work together to ensure efficient airflow and low noise levels.

- Different types of centrifugal fans cater to various needs, from energy-efficient models to those designed for high temperatures or corrosive environments.

- Choosing the right fan involves considering airflow requirements, pressure needs, and environmental conditions to ensure optimal performance.

- Centrifugal fans from fanacdc are built for durability and efficiency, making them a reliable choice for industrial and commercial applications.

What is a Centrifugal Fan

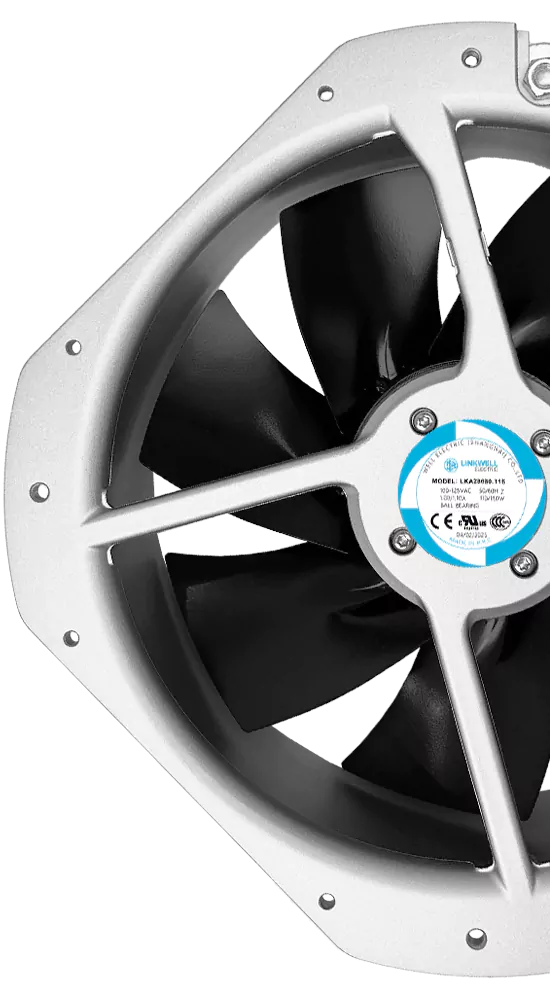

You might ask yourself, what is a centrifugal fan and why does it matter for your equipment? A centrifugal fan is a mechanical device that moves air or gases by spinning an impeller inside a protective housing. When you turn on the fan, the impeller rotates and pushes air outward, changing its direction by 90 degrees. This action creates high-pressure airflow, which is perfect for cooling, ventilation, and filtration in tough environments. If you need reliable performance, centrifugal fans from fanacdc deliver the power and durability you expect.

Centrifugal Fan Structure

Let’s break down what makes a centrifugal fan work so well. Each part plays a key role in keeping your systems cool and efficient. Here’s a quick look at the main components and how they help:

| Component | Contribution to Performance |

|---|---|

| Impeller | Generates airflow through various designs, crucial for efficiency and application suitability. |

| Motor | Drives the impeller, converting electrical energy into mechanical motion, affecting efficiency. |

| Housing | Protects internal components, optimizes airflow, and reduces noise. |

| Bearings | Allow smooth rotation with minimal friction, reducing heat and extending lifespan. |

| Shaft | Transfers power from the motor to the impeller, ensuring smooth operation and alignment. |

| Frame/Bracket | Provides support and reduces vibration, maintaining alignment for peak performance. |

When you choose a centrifugal fan from fanacdc, you get a product built with flame-retardant housings, sealed bearings, and a high-efficiency motor. These features help the fan run smoothly, even in harsh industrial settings. The impeller design is especially important. It controls how much air the fan moves and how much pressure it can create. You’ll notice that the housing keeps everything safe and quiet, while the bearings and shaft make sure the impeller spins without trouble.

Types of Centrifugal Fans

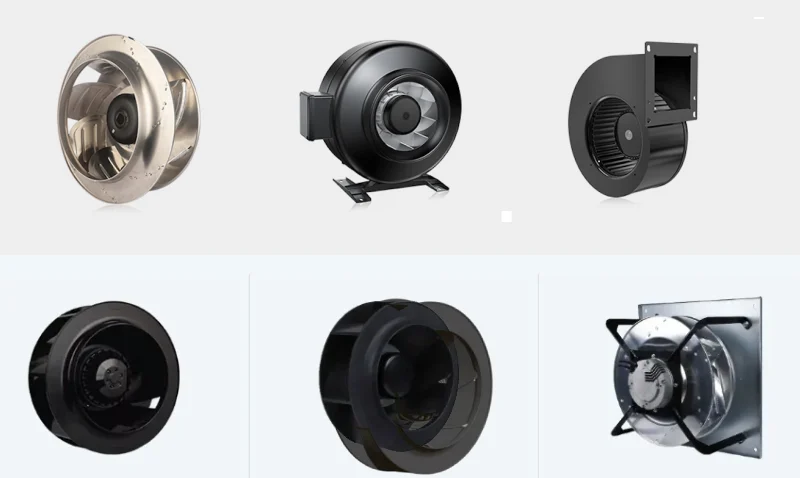

Now, let’s talk about the different types of centrifugal fans you might find. You’ll see that each type has its own strengths, depending on your needs.

- Direct-driven fans: These are compact and easy to maintain. You’ll use them for clean air applications.

- Belt-driven fans: If you want adjustable airflow and pressure, these are a great choice for industrial systems.

- Backward-curved blade fans: These fans are more energy-efficient and work well in high-pressure situations.

- Forward-curved blade fans: You’ll get higher air volumes at lower pressures, which is perfect for compact ventilation units.

- ATEX-certified fans: These are designed for explosive environments and meet strict safety standards.

- Smoke extraction fans: You’ll use these for smoke control, especially in emergency situations.

- Corrosion-resistant fans: Made from tough materials like plastic or stainless steel, these fans last longer in harsh conditions.

- High-temperature fans: If you need cooling in extreme heat, these fans can handle temperatures up to 400°C.

You might wonder how the blade design affects efficiency. Backward-curved fans can reach up to 85% static efficiency, which means they use less energy and handle high-pressure jobs better. Forward-curved fans usually hit 55% to 65% efficiency, so they’re best for moving large volumes of air quietly in low-pressure settings. The shape of the blades makes a big difference. Backward-curved blades curve away from the direction of rotation, giving you better performance in demanding applications. Forward-curved blades curve with the rotation, making them quieter but less efficient overall.

If you’re still asking, what is a centrifugal fan, just remember: it’s a powerful tool for moving air, built with smart engineering and tough materials. Centrifugal fans from fanacdc come in many shapes and sizes, so you can always find the right fan for your job.

How Does a Centrifugal Fan Work

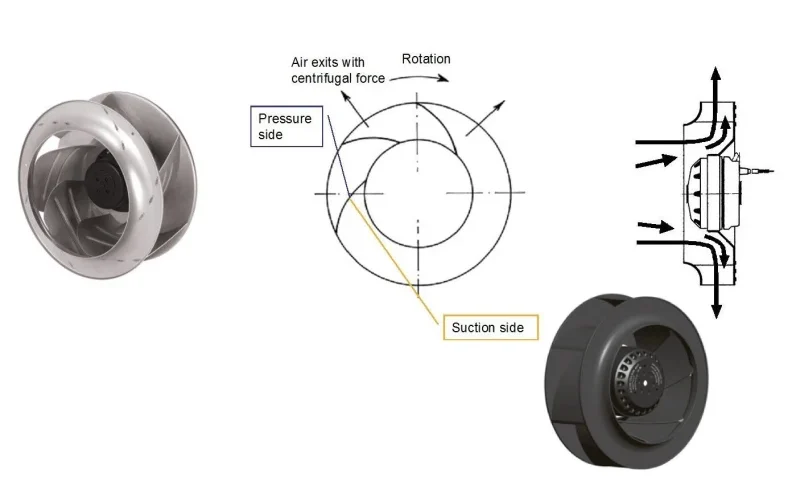

Working Principle

You might wonder, how does a centrifugal fan work when you flip the switch. The answer starts with the spinning impeller inside the fan. This part acts like the heart of the system. When the motor powers up, the impeller rotates quickly. You’ll see air get pulled in through the center, right along the axis of the motor. The impeller blades grab the air and push it outward, changing the direction by 90 degrees. That’s the secret behind the strong airflow you get from centrifugal fans.

Here’s what happens inside every centrifugal fan:

- The impeller spins and creates kinetic energy.

- Air enters axially, moving straight into the center of the fan.

- The impeller throws the air outward, sending it radially toward the edges.

- The housing guides the air, making sure it exits in the right direction.

- You get a steady stream of air, even if your system has lots of resistance.

You’ll notice that centrifugal fans work well in tough conditions. They stay quiet and reliable, even when you run them for hours. The design lets you use these fans in places where you need strong airflow and high pressure. If you look at a fanacdc centrifugal fan, you’ll see a sturdy build and a smart impeller design. That’s why these fans keep your equipment cool and safe.

Airflow and Pressure

Let’s dig deeper into how does a centrifugal fan work to create airflow and pressure. When air moves through the impeller, it changes direction from axial to radial. This shift is what gives centrifugal fans their power. The impeller’s rotation builds up pressure inside the housing. The volute casing helps direct the airflow and boosts static pressure. You get air pushed out at a much higher pressure than it came in.

Here’s a quick look at how airflow and pressure work in centrifugal fans:

- Air comes in straight, then gets spun out sideways.

- The impeller creates a pressure difference, so air flows from low to high pressure.

- The casing shapes the airflow, making it stronger and more focused.

If you check the specs for industrial centrifugal fans, you’ll see they can handle a wide range of pressure needs. Take a look at this table to see typical pressure ranges:

| Pressure Range |

|---|

| 0-1.5″ s.p. |

| 1.5-3″ s.p. |

| 3-8″ s.p. |

| 8-25″ s.p. |

You’ll find that fanacdc centrifugal fans can reach high static pressure, making them perfect for HVAC systems, filtration, and power equipment. The spinning impeller and smart housing design work together to deliver reliable airflow, even when your system has lots of ducts or filters. That’s how does a centrifugal fan work to keep your operations running smoothly.

Tip: If you need a fan that handles tough jobs and keeps noise low, centrifugal fans from fanacdc are a solid choice. Their impeller design and strong housing make them stand out in industrial settings.

Centrifugal Fan Features by fanacdc

Product Advantages

When you look for a fan that delivers top performance, you want something that stands out in every way. The centrifugal fan from fanacdc gives you just that. You get a fan with a strong impeller that pushes air with high static pressure. This means your system gets steady airflow, even if it faces lots of resistance. The impeller design also keeps noise low and airflow smooth.

You might wonder about energy use. DC centrifugal fans from fanacdc use advanced motor technology. They can cut power use by up to 70% compared to old-style AC fans. That means you save energy and money while getting better performance. These fans work well in tough places, like factories or power plants. Their robust build lets them handle heat, dust, and long hours of operation.

Here’s what makes these fans a smart choice:

- High static pressure for strong airflow in demanding systems

- Energy-efficient motors that beat industry standards

- Durable impeller and housing for long-lasting performance

- Quiet operation, even at high speeds

- Flexible sizes and models for different needs

You can count on a centrifugal fan from fanacdc to last. Most centrifugal fans run for 15 to 20 years in industrial settings. With regular care, your fan will keep your equipment cool for a long time.

Certifications and Reliability

You want a fan you can trust. That’s why fanacdc centrifugal fans come with top certifications. These show you get quality, safety, and great performance every time.

| Certification | Description |

|---|---|

| ISO9001 | Quality management system standard ensuring consistent quality in products and services. |

| ISO14001 | Environmental management standard promoting sustainable practices. |

| RoHS | Restricts hazardous substances in electrical and electronic equipment. |

| UL | Safety certification indicating compliance with safety standards. |

| CE | Conformity marking indicating compliance with health, safety, and environmental protection standards. |

| TÜV | Certification ensuring product safety and quality through rigorous testing. |

You can see that each centrifugal fan meets strict rules for safety and the environment. These certifications mean your fans will work safely and reliably, no matter where you use them. When you choose fanacdc, you pick a partner who cares about quality and your peace of mind.

Applications of Centrifugal Fans

Industrial Uses

You see centrifugal fans working hard in many industries. These fans keep factories cool and safe. You might spot a centrifugal fan in a cement plant, where it cools clinker and helps manage heat. Glass manufacturers use these fans to control oven wall temperatures. You also find them in power generation, moving cooling air through condensers. If you work in a cleanroom, these fans help control air pollution and keep the space dust-free.

Here are some common industrial uses for centrifugal fans:

- Heat reduction in heavy industries

- Cooling air for clinker in cement production

- Temperature management in glass manufacturing

- HVAC systems for air movement and distribution

- Industrial ventilation for removing fumes and pollutants

- Material handling for moving bulk materials

- Power generation for condenser cooling

- Dedusting processes in manufacturing

The impeller design in these fans creates strong airflow and high static pressure. You get reliable performance, even when your system faces tough conditions. The aerodynamic impeller also keeps energy use low and airflow steady.

Tip: If you need a fan that handles dust, heat, or chemicals, choose a centrifugal fan with a robust impeller and durable housing.

Commercial Uses

You find centrifugal fans in many commercial spaces. Offices, hospitals, and schools rely on these fans for clean air and quiet operation. HVAC systems use centrifugal fans to move large volumes of air with low noise. Chemical plants and wastewater facilities need fans with corrosion-resistant materials, like stainless steel or FRP, to handle harsh chemicals. High-temperature applications, such as power plants, use robust fans with radial blade designs.

Here’s a table showing how different sectors use centrifugal fans:

| Commercial Sector | Specific Requirements |

|---|---|

| Clean Air Systems and Commercial HVAC | Efficiency, low noise, high-volume airflow |

| Industrial Ventilation | Durable fans for fume exhaust and dust collection |

| Chemical and Wastewater Plants | Corrosion-resistant impeller and housing |

| High-Temperature Applications | Robust fans for extreme heat |

| Material Conveying | Radial blade fans for moving abrasive or sticky materials |

You get precise airflow control and stable performance with these fans. The impeller design lets you save energy and keep your system running smoothly. If you want reliable air movement in your building, centrifugal fans deliver the results you need.

Centrifugal vs Radial Fans

Key Differences

You might wonder how a centrifugal fan stacks up against a radial fan. Both fans move air, but they do it in different ways. If you look at their airflow and pressure, you’ll see some clear differences.

Here’s a table to help you compare:

| Fan Type | Airflow Characteristics | Pressure Characteristics |

|---|---|---|

| Centrifugal | Low-volume, high-pressure airflow | Capable of creating pressure up to 10 inwg |

| Radial | High-volume, low-pressure airflow | Static pressure around 0.5 inwg |

A centrifugal fan pushes air with more pressure, making it great for systems with lots of resistance, like long ducts or filters. Radial fans move more air but at lower pressure, so you’ll use them where you need lots of airflow but not much force.

Maintenance is another thing to think about. Centrifugal fans work harder and may need more frequent checks because they handle higher pressure and complex ductwork. Radial fans have a simpler design, which means less dust buildup and fewer maintenance stops. If your workspace gets dusty, a radial fan might save you time.

Tip: Centrifugal fans are perfect for high-pressure jobs. Radial fans shine in places where you need lots of airflow and easy upkeep.

Choosing the Right Fan

Picking the right fan for your job depends on a few key factors. You want to match the fan to your system’s needs. Here’s what you should look at:

- Airflow rate: Figure out how much air you need to move.

- Pressure drop: Check if your system has filters or long ducts that slow down airflow.

- Material to be handled: Clean air works well with backward-curved blades. Dusty or sticky air fits better with radial wheels.

- Space constraints: Make sure you have enough room for installation and maintenance.

- Air quality: If you deal with chemicals or dust, choose a fan with the right materials.

- Temperature control: High heat calls for fans built to handle it.

- Safety features: Always look for fans with safety certifications.

If you need strong pressure and reliable cooling, a centrifugal fan from fanacdc is a solid choice. For high-volume airflow and simple maintenance, a radial fan might fit your needs better. You can always reach out to fanacdc for expert advice and find the best fan for your application.

Conclusion

You’ve learned a lot about how a centrifugal fan works and why it matters for your equipment. These fans use a spinning impeller to move air with power and precision. You get strong airflow and high pressure, which helps keep your systems cool and safe. When you choose a fan from fanacdc, you pick a product built for tough jobs and long-lasting performance.

Let’s look at the key benefits you get when you use centrifugal fans in industrial spaces:

| Benefit | Description |

|---|---|

| Energy Efficiency | These fans can cut power use by up to 40%, saving you money and lowering your carbon footprint. |

| Air Pollution Control | Fans help remove dust, gases, and pollutants from your workspace. |

| Waste Heat Recovery | You can use fans to capture heat from exhaust and put it to good use. |

| Durability | Fans made from corrosion-resistant materials last longer and reduce waste. |

| Improved Indoor Air Quality | Fans keep the air fresh and clean in busy facilities. |

| Integration with Renewable Energy | Fans work well in energy-efficient HVAC and renewable energy systems. |

You see these fans in factories, offices, and power plants. They handle heat, dust, and chemicals with ease. The fan design lets you control airflow and pressure, so your equipment runs smoothly. You also get peace of mind knowing that fanacdc fans meet strict safety and quality standards.

Tip: If you want a fan that saves energy, controls pollution, and lasts for years, centrifugal fans from fanacdc are a smart choice for any industrial or commercial project.

You now know how a centrifugal fan works, what makes it special, and why it’s trusted by top brands. If you need reliable cooling, strong airflow, and proven durability, fanacdc fans deliver every time.

You now understand how a centrifugal fan works and why these fans matter for your cooling needs. When you choose a fan from fanacdc, you get high-pressure airflow, energy savings, and reliable performance. These fans handle tough environments and keep your equipment safe. Before you pick a fan, think about airflow, pressure, noise, and environmental conditions. Take a look at what customers say about these fans:

| Customer Type | Testimonial |

|---|---|

| Manufacturing Facility Manager | Praised the fans for exceptional performance and reliability, noting improvements in air quality. |

| Warehouse Owner | Commended the energy efficiency of the fans, highlighting reduced energy costs and improved air circulation. |

If you want a fan that lasts and delivers results, fanacdc fans are the smart choice for any industrial or commercial project.

FAQ

What is a centrifugal fan?

You use a centrifugal fan to move air by spinning an impeller. The fan pushes air outward and changes its direction. This design helps you get strong airflow and high pressure for cooling and ventilation.

How do you choose the right centrifugal fan?

You look at airflow needs, pressure, space, and noise. Check your system’s requirements. Pick a fan with the right size and certifications. If you need help, ask fanacdc for advice.

Where do you use centrifugal fans?

You find centrifugal fans in factories, offices, hospitals, and power plants. They work in HVAC systems, dust collection, refrigeration, and material handling. These fans help you keep air clean and equipment cool.

How do you control the speed of a centrifugal fan?

You use a variable frequency drive (VFD) to adjust the fan’s speed. This lets you control airflow and save energy. You can set the speed to match your system’s needs.