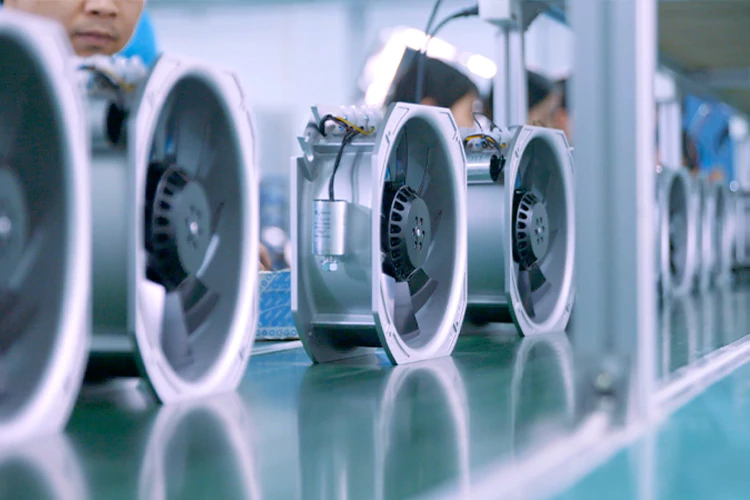

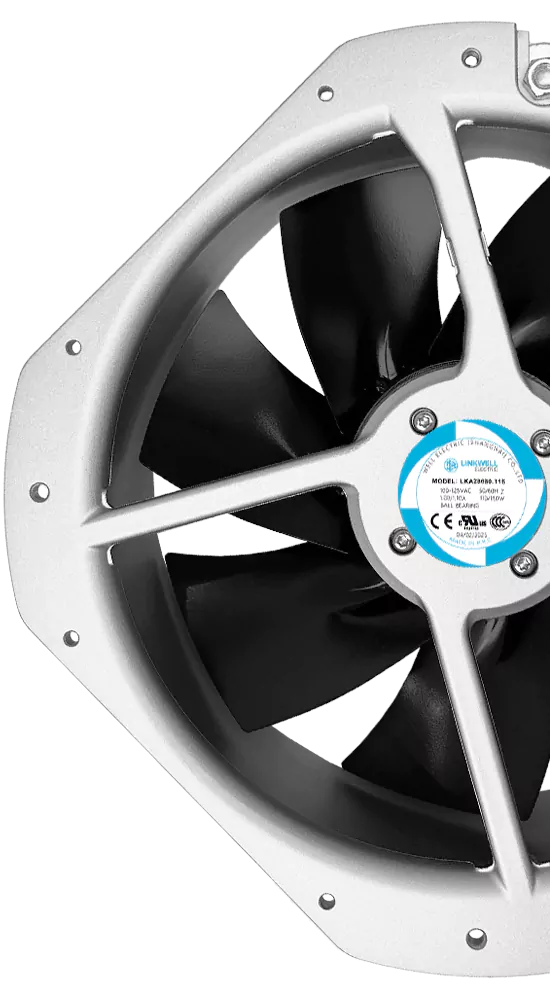

High-performance AC cooling fans engineered for demanding applications

80-280mm

Size Range

110 V / 220 V

Voltage

–30°C ~ 80°C

Operation Temperature

50,000 hour

Service Life

Fan

Model

Size

(mm)

Voltage

(VAC)

Power

(W)

Speed

(RPM)

Airflow

(CFM)

Our fans use industrial-grade, flame-retardant engineering plastics designed for strength, temperature resistance, and insulation performance.

Reinforced rib structures prevent deformation and maintain long-term reliability under continuous vibration and heat loads, making them ideal for demanding industrial environments.

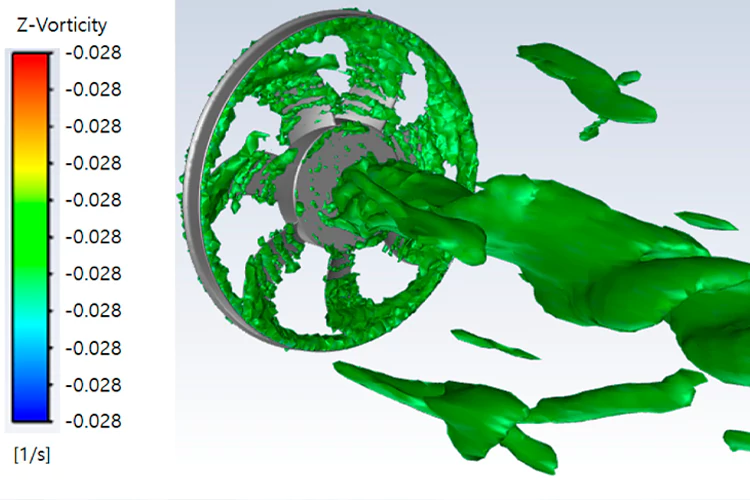

We utilize high-efficiency motors and aerodynamic blade design to provide strong airflow and stable cooling with reduced noise and power consumption.

Each model is engineered for balanced rotation, smooth speed response, and extended service life.

Every fan undergoes a complete quality assurance process — from incoming materials to final product testing — ensuring consistent performance and durability in real-world conditions.

We continuously invest in fan engineering and manufacturing technology to deliver better efficiency, reliability, and durability. Our innovations focus on improving airflow efficiency, extending service life, and meeting evolving industrial requirements.

Our Innovation Focus:

Our technology strengths enable reliable solutions across industrial control, power electronics, telecom, and energy applications.

Ideal for automation equipment and control cabinets. Ensures stable temperature control, supports continuous operation, and prevents component overheating in high-duty industrial environments.

Designed for PV inverters, energy storage systems, and power conversion equipment.

Provides reliable cooling for high-power electronics, ensuring efficiency and long-term system stability.

Ensures consistent airflow and temperature regulation for communication systems and data equipment. Supports reliable uptime and maintains equipment performance under continuous load.

We offer customization across size, mounting structure, voltage, and speed curves to ensure precise performance fit.

Whether your system requires compact dimensions, higher static pressure, or specific airflow output, we engineer cooling solutions that integrate seamlessly and operate efficiently.

For demanding environments, we offer enhanced protection including IP-rated designs, corrosion-resistant materials, and high-temperature operation.

These upgrades ensure reliable long-term performance in outdoor, coastal, industrial, and high-humidity conditions, delivering stable cooling where reliability matters most.

Our engineering team supports fast concept evaluation and rapid prototype development, helping you accelerate product validation and shorten time-to-market.

From early-stage design to mass production, we ensure smooth project execution and dependable lead times for urgent programs.

An AC fan is a cooling device powered by alternating current (usually 110V/220V or 50/60Hz). It uses an AC induction or shaded-pole motor to convert electrical energy into mechanical airflow. The motor’s rotating magnetic field drives the fan blades, creating steady airflow for heat dissipation and ventilation.

The key difference from a DC fan lies in motor structure and power supply. AC fans run directly from the AC grid and typically maintain fixed speed based on voltage and frequency. DC fans use a brushless DC motor, requiring rectification and electronic control, allowing precise speed regulation and higher energy efficiency.

AC fans are valued for simplicity, durability, and cost-effectiveness, especially in industrial environments. DC fans excel in energy savings, speed control, and smart monitoring. Choosing between them depends on application needs—AC fans suit continuous, robust cooling, while DC fans are ideal for energy-controlled or intelligent systems.

AC fans are commonly used in industrial, commercial, and high-power electronic environments requiring reliable, continuous cooling. Typical applications include control cabinets, automation systems, industrial machinery, power electronics, HVAC systems, refrigeration equipment, air purification devices, and telecom base stations. Due to their strong stability and long design life, AC fans are also popular in motor drives, welding machines, generators, UPS systems, medical sterilization units, and food processing equipment.

They are particularly effective in applications with stable input power and consistent ventilation demands. In industrial facilities, they protect sensitive electronics from overheating, reduce failure rates, and improve system longevity. In commercial ventilation systems, AC fans support airflow circulation and temperature balance.

Overall, AC fans are chosen when durability, reliability, and cost-efficiency are priorities, making them a preferred solution in heavy-duty and long-operation scenarios.

Industrial AC fans are typically offered in standard global voltage formats, ensuring compatibility with regional power systems. Common voltage configurations include 110/120V AC and 220/230/240V AC, available in both 50Hz and 60Hz frequency options. Some models support dual-voltage design for flexible installation across multiple regions and industries.

Frequency differences impact motor rotational speed; AC fans running at 60Hz generally operate slightly faster than those at 50Hz, resulting in higher airflow output.

To ensure proper operation and safety, selecting the correct voltage and frequency is essential. Always verify system requirements and compliance standards before installation. Matching fan specifications with local electrical codes helps ensure performance stability, extended service life, and long-term reliability.

Yes, AC fans can achieve speed control, but the method differs from DC fans. Unlike brushless DC fans, which support PWM and tachometer feedback, AC fans typically rely on external control solutions. Common approaches include voltage regulation, frequency control (via VFDs), transformer-based adjustment, and phase-cut control.

Voltage regulation allows step-down speed control but may reduce torque. Frequency converters are most effective for precise control and maintaining fan efficiency, especially in industrial systems. Thermostat-based on/off control is also widely used to activate fans only when temperature thresholds are reached.

While AC fan speed control is possible, it is not as fine-tuned or energy-efficient as DC fan technology. For applications that demand precise airflow modulation or intelligent thermal management, DC or EC fans may be more suitable. However, for stable and continuous airflow needs, AC fan control systems perform reliably and economically.

AC fans generally offer a lower initial purchase cost compared to DC fans due to simpler motor design, mature manufacturing technology, and fewer electronic components. For industrial applications, AC fans provide excellent value where stable airflow and long-term durability are priorities. They are widely used in control cabinets, power systems, and factory equipment because of their reliability and cost-effectiveness.

DC fans, while more expensive upfront, include brushless motor technology and built-in electronic controls. They deliver higher energy efficiency, advanced speed regulation, and extended service life for certain models. For example, high-quality AC fans typically operate for over 50,000 hours, while premium DC fans may reach 70,000 hours depending on bearing type and environment.

When evaluating cost, total cost of ownership should be considered. AC fans excel in environments needing constant-speed operation and long run cycles, whereas DC fans may reduce energy and maintenance costs in smart or variable-speed systems.

The lifespan of an AC fan depends on component quality, bearing type, operating temperature, and duty cycle. High-quality industrial AC fans commonly achieve 50,000 hours or more of continuous operation under standard conditions. Fans equipped with ball bearings typically offer longer service life and better performance in high-temperature or vertical-mount installations compared to sleeve-bearing models.

Operating environment plays a major role. High dust, humidity, vibration, and corrosive atmospheres can shorten lifespan if proper sealing or protective coatings are not used. Fans designed with IP-rated enclosures and corrosion-resistant materials help ensure long-term reliability in challenging industrial settings.

Regular cleaning to remove dust buildup and ensuring proper ventilation clearance will also support extended service life. When sourced from certified manufacturers and used within rated conditions, AC fans provide dependable and durable cooling for demanding applications.

AC fans provide several notable advantages: strong and consistent airflow, robust structure, long service life, and economical pricing. They are ideal for industrial environments requiring steady cooling without complex control needs. AC motors also deliver reliable startup torque and handle continuous duty cycles effectively. Their simple architecture and low maintenance requirements make them a dependable solution in harsh operational settings.

However, compared to DC and EC fans, AC fans consume more power and have limited speed-control flexibility. They cannot achieve the same energy-saving performance or intelligent monitoring functions found in brushless DC technology. Noise levels may also be higher in sensitive applications, depending on fan size and airflow demand.

Overall, AC fans are a reliable, cost-efficient choice for traditional industrial cooling, while DC and EC models may be preferred for smart, energy-efficient, and variable-speed environments.

Selecting an AC fan requires evaluating airflow performance, static pressure, operating temperature range, noise level, and service life. Airflow (CFM or m³/h) determines cooling capacity, while static pressure indicates performance in systems with resistance such as filters or ducting. High-temperature ratings and durable bearing systems ensure longevity in industrial environments.

Voltage and frequency compatibility (e.g., 110V/220V, 50/60Hz) must match the local power system. Environmental protection features like IP ratings, salt-spray resistance, or dust protection may be necessary for outdoor or corrosive environments.

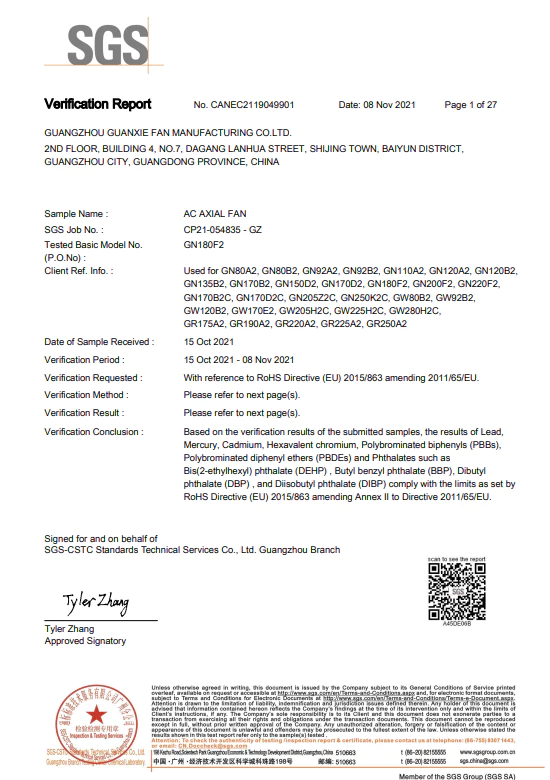

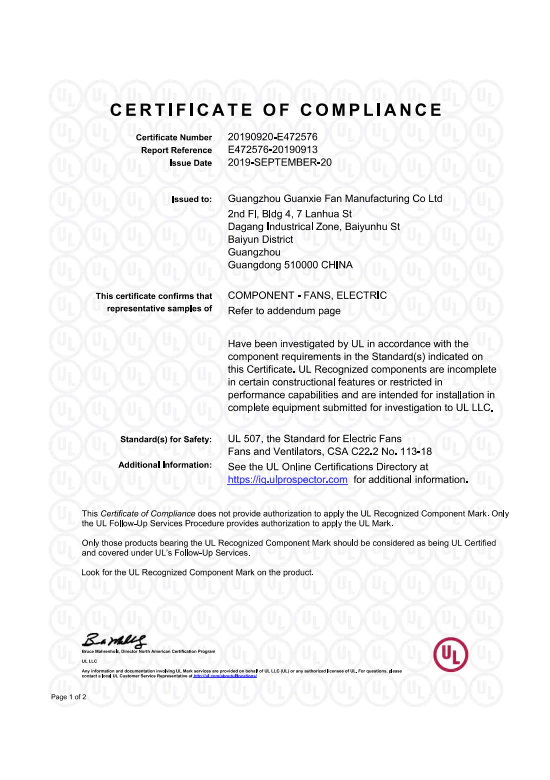

Safety and compliance certifications (UL, CE, RoHS) help ensure product quality and safe operation. Mechanical factors such as fan size, mounting type, and connector format also influence system integration. By reviewing these technical specifications, users can select a fan that meets performance expectations and supports long-term reliability.

AC fans are designed for stable cooling with predictable noise characteristics. Noise level depends on fan size, blade geometry, motor efficiency, and airflow requirements. Industrial AC fans typically operate at higher noise levels when delivering strong airflow, though optimized blade designs help minimize turbulence and vibration.

In terms of electromagnetic interference (EMI), AC fans generally produce minimal EMI because they lack the high-frequency switching components found in DC fan drivers. This makes them suitable for environments sensitive to electrical interference, such as industrial control rooms and power electronics facilities. High-quality AC fans follow EMI compliance standards to ensure safe operation alongside other equipment.

Proper installation, balanced fan blades, and routine cleaning further help maintain low noise and smooth operation throughout the product’s lifespan.

Yes, AC fans are typically easier to install and connect. They operate directly from standard AC mains power without the need for an external converter, controller, or driver board. Most units include two-wire or three-wire connections and clearly labeled terminals, making setup straightforward. Mounting options include screw holes, flange brackets, or panel-mount frames, suitable for quick integration into industrial systems.

In contrast, DC and EC fans may require regulated power supplies, PWM controllers, or signal monitoring circuits. While these features deliver advanced control, they add installation complexity.

For users prioritizing fast deployment, minimal wiring, and plug-and-play operation, AC fans offer significant convenience. Always confirm voltage and frequency compatibility before installation to ensure safe and reliable operation.

WhatsApp us

Curious how LINKWELL’s cooling solutions can address your business challenges? Let’s connect and discuss your needs.