Deciding on an axial vs radial fan for your industrial setup can be challenging. You need to consider factors like airflow, pressure, and the specific environment where the fan will operate. In many cases, axial fans deliver superior energy efficiency, while radial fans excel in compact spaces and can be more cost-effective.

Noise is another important consideration—axial fans are typically louder than radial fans. Ultimately, your application will determine which fan is best suited for your needs. With years of expertise, fanacdc is here to guide you in selecting the ideal axial vs radial fan for any industrial requirement.

Key Takeaways

- Axial fans are best for high airflow in open spaces, making them ideal for ventilation and cooling applications.

- Radial fans excel in high-pressure situations, perfect for moving air through ducts and overcoming resistance.

- Consider your specific needs, such as airflow direction and pressure requirements, when choosing between axial and radial fans.

- Axial fans are generally quieter and easier to maintain, while radial fans may require more upkeep due to their complex design.

- For customized solutions and expert advice, reach out to fanacdc to find the right fan for your industrial needs.

Axial vs Radial Fan Overview

What is an Axial Fan?

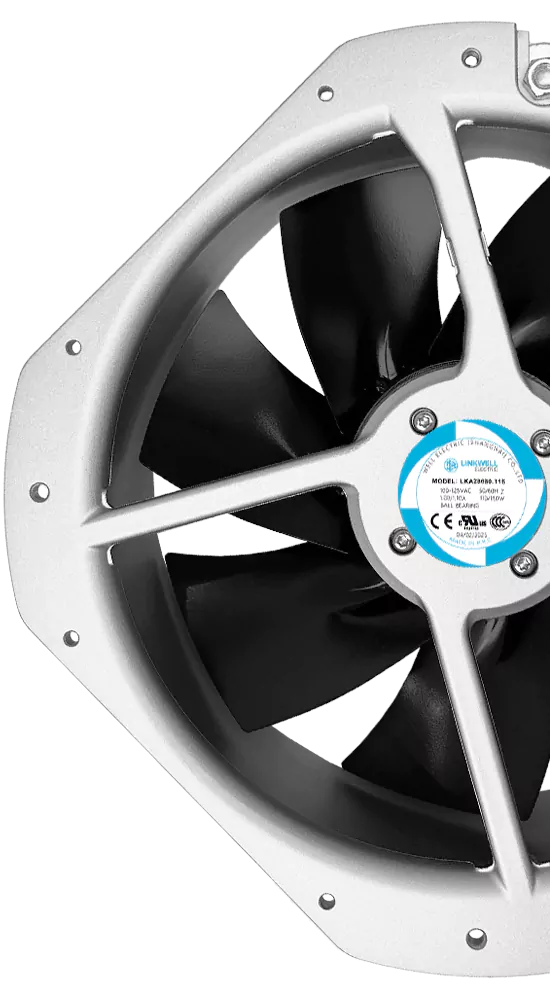

When you picture a classic cooling fan, you probably imagine an axial fan. This type of fan uses blades that spin around a central axis, much like the propeller on an airplane. Air moves straight through the fan, entering from one side and exiting the other, always traveling parallel to the shaft. You often see an axial fan in places where you need to move a lot of air quickly, like in ventilation systems or as an industrial strength fan for large rooms. Because of their design, axial fans work best when you want high airflow but do not need to push air against much resistance.

What is a Radial Fan?

A radial fan, sometimes called a centrifugal fan, looks and works a bit differently. Instead of moving air straight through, a radial fan pulls air in from the center and then pushes it out at a 90-degree angle. This design lets the radial fan create higher pressure, making it perfect for situations where air needs to travel through long ducts or face obstacles. You might find a radial fan in a garage industrial fan setup or as a blower industrial fan in factories. The radial fan stands out when you need to overcome resistance and keep air moving strong.

Tip: If you need to move air through filters or long pipes, a radial fan is usually your best bet.

Working Principles

Both fans use spinning blades to move air, but the way they direct airflow sets them apart. An axial fan spins its blades to pull air straight through, making it great for open spaces. A radial fan, on the other hand, uses its impeller to fling air outward, changing the direction by 90 degrees. This difference means a radial fan can handle higher pressure, while an axial fan delivers more volume. Here’s a quick comparison to help you see the main differences:

| Feature | Radial Fan | Axial Fan |

|---|---|---|

| Airflow Direction | 90 degrees to the inlet | Parallel to the axis |

| Pressure Capabilities | High pressure, overcomes resistance | Low pressure, high volume flow |

| Applications | Duct systems, industrial processes | Ventilation, cooling, exhaust |

When you choose between an axial fan and a radial fan, think about your space and what you need the fan to do. If you want to move a lot of air in a straight line, go with an axial fan. If you need to push air through a maze of ducts or filters, a radial fan will serve you better.

Key Differences: Axial vs Radial Fan

Airflow Pattern

When you look at the airflow characteristics of an axial vs radial fan, you notice a big difference in how each fan moves air. An axial fan pushes air straight through, parallel to the shaft. This creates a direct path, which works well for general ventilation and cooling large open spaces. You often see this design in ventilation systems or as an industrial strength fan in factories.

A radial fan, sometimes called a centrifugal fan, draws air into the center and then throws it out at a right angle. This 90-degree turn lets the fan create a more focused stream of air. You might use a radial fan in a garage industrial fan setup or as a blower industrial fan when you need to move air through ducts or filters. Here’s a quick table to help you compare:

| Fan Type | Airflow Direction | Pressure Level | Volume Displacement | Applications |

|---|---|---|---|---|

| Axial Fan | Parallel to the axis | Low | High | Cooling towers, ventilation systems |

| Radial Fan | Perpendicular to the axis | High | Low | HVAC systems, industrial processes |

If you need to move a lot of air in a straight line, go with an axial blade fan. For concentrated airflow or when you need to overcome resistance, a radial fan is your best choice.

Pressure and Volume

Pressure capabilities and volume are two of the most important factors when choosing between an axial vs radial fan. An axial fan delivers a high volume of air but at a lower pressure. This makes it perfect for general ventilation, exhaust, and cooling applications where you want to move a lot of air without much resistance.

A radial fan, on the other hand, shines when you need higher pressure. It can push air through long ducts, filters, or other obstacles. The volume of air moved by a radial fan is usually lower than that of an axial fan, but the pressure capabilities are much higher. Here’s a simple comparison:

| Fan Type | Pressure Characteristics | Volume Characteristics |

|---|---|---|

| Radial Fan | Higher pressure | Moderate volume |

| Axial Fan | Lower pressure | Higher volume |

- Radial fans work best in air conditioning, HVAC, and industrial processes where you need to overcome resistance.

- Axial fans are ideal for moving large volumes of air at low pressure, like in exhaust systems or general ventilation.

Efficiency and Energy Use

Energy efficiency is a big deal in industrial settings. You want a fan that does the job without wasting power. An axial fan usually offers better energy efficiency in low-resistance, high-volume situations. If you need to ventilate a warehouse or cool a large room, an axial fan will move a lot of air while using less energy.

A radial fan becomes more efficient when you need to deal with higher static pressure. If your system has lots of bends, filters, or long ducts, a radial fan maintains good efficiency even under tough conditions. Here’s a quick look:

| Fan Type | Efficiency Context |

|---|---|

| Axial Fan | Higher efficiency in low resistance, high airflow applications (e.g., open space ventilation). |

| Radial Fan | More efficient in medium to high static pressure applications, maintaining good efficiency under high-pressure conditions. |

You can boost energy efficiency even more by choosing fans with advanced motor technology or smart controls. Many modern industrial fans, including those from fanacdc, use optimized blade designs and brushless motors to save energy and reduce costs.

Noise and Maintenance

Noise and maintenance are important when you plan to use a fan in an industrial environment. Axial fans tend to be quieter, especially at lower speeds. Their simple design means fewer moving parts, which leads to less maintenance and lower costs. You can easily repair or replace parts on an axial fan, making it a popular choice for ventilation systems and industrial stand up fans.

Radial fans, with their more complex structure, can be noisier and require more care. They have more components, like impellers, which means more maintenance over time. If you use a radial fan in a blower industrial fan setup or as a fan radial in a demanding environment, you should plan for regular checks and upkeep.

- Axial fans are easier to maintain and have fewer parts, so you spend less time and money on repairs.

- Radial fans need more maintenance because of their design, but they handle tough jobs and higher pressure.

When you compare the operational lifespan, axial fans often last longer due to their simpler build. Radial fans, while durable, may wear out faster if used in harsh conditions. Always consider your environment and how much maintenance you’re willing to do when choosing between an axial vs radial fan.

Application Suitability in Industry

Axial Fan Applications

When you look at high airflow applications, the axial fan stands out as a top choice. You often see this fan in places where you need to move a lot of air quickly and efficiently. Here are some common applications where an axial fan shines:

- Building ventilation: You find these fans in ducts, helping ventilate large rooms and open spaces.

- Cooling systems: Axial fans work in cooling towers and chillers, keeping industrial equipment at safe temperatures.

- Exhaust systems: They remove stale air and improve air quality in factories and warehouses.

- Agricultural settings: Greenhouses and poultry houses use axial fans to bring in fresh air and keep conditions stable.

- Data centers: These fans regulate temperature, preventing servers and electronics from overheating.

- Electronics: Axial fans cool components in computers and server racks.

- Automotive sector: They play a role in engine cooling and climate control.

If you need an industrial strength fan for a large warehouse or a garage industrial fan to keep air moving, the axial blade fan is a reliable solution. The fanacdc AC Fans are perfect for these typical uses. They deliver high volume airflow, operate quietly, and last for years. You can use them for industrial ventilation, exhaust systems, or even as industrial stand up fans in busy workspaces. Their robust design and simple installation make them a favorite for many industries.

Tip: Choose an axial fan when your main goal is to move a lot of air in a straight line with minimal resistance.

Radial Fan Applications

Radial fans, also known as centrifugal fans, excel in situations where you need to push air through obstacles or create higher pressure. You see these fans in a wide range of industrial environments. Here are some of their most common applications:

- HVAC systems: Radial fans play a crucial role in circulating air and maintaining indoor air quality.

- Dust collection: These fans efficiently extract dust and particles, which is vital for health and safety.

- Fume extraction: Laboratories and manufacturing plants use radial fans to remove harmful fumes and gases.

- Cooling systems: Radial fans keep electronic components cool, preventing overheating and ensuring reliable performance.

- Material handling: Industries like food processing and chemical manufacturing use these fans to move materials through pneumatic conveying systems.

If you need a blower industrial fan for a factory or a fan radial for a demanding environment, the fanacdc Centrifugal Fan is a great fit. This fan handles high-pressure tasks, moves air through long ducts, and works well in harsh conditions. You can rely on it for dust collection, fume extraction, and specialized ventilation. The robust airflow and long service life make it ideal for continuous operation in tough settings.

Note: Radial fans are your go-to for applications where air needs to travel through filters, ducts, or face resistance.

Choosing the Right Fan

Selecting between an axial vs radial fan depends on your specific needs. You want to consider several factors to ensure the best application suitability for your project. Here’s a quick table to help you compare:

| Criteria | Axial Fans | Centrifugal Fans |

|---|---|---|

| Airflow Requirements | High airflow at low pressure | High-pressure airflow through ducts |

| Space Constraints | Compact design for tight spaces | Requires more room due to larger size |

| Environmental Conditions | Suitable for clean environments | Excels in harsh conditions with dust or gases |

| Budget Considerations | Usually cheaper upfront, higher maintenance costs | Higher initial cost, potentially lower maintenance costs |

You should also think about:

- Fan design: Axial fans work best in large open areas, while centrifugal fans are better for duct-based tasks.

- Volume of air: Figure out the required CFM to maintain safe and comfortable conditions.

- Static pressure: If you need to overcome resistance, a blower industrial fan or centrifugal fan is the right choice.

- Motor and blade quality: High-quality fans, like those from fanacdc, ensure longevity and reliability.

Here are some ideal situations for axial fans:

- You need high volume airflow in open spaces.

- Your environment is clean, like a data center or electronics room.

- You want a cost-effective solution for general ventilation or exhaust systems.

And here are ideal situations for radial fans:

- You need to move air through long ducts, filters, or obstacles.

- Your workspace has dust, fumes, or harsh conditions.

- You require a garage industrial fan or blower industrial fan for heavy-duty tasks.

Fanacdc offers both AC Fans and Centrifugal Fans to cover all these needs. Their products provide robust airflow, simple control, and long service life under continuous operation. Whether you need industrial fans for sale for a new project or want to upgrade your current system, you can trust fanacdc to deliver the right solution for any industrial scenario.

If you’re unsure about your selection, reach out to fanacdc for expert advice. Their team can help you match the perfect fan to your unique requirements.

fanacdc Solutions for Industrial Fans

Centrifugal Fan Features

If you need a fan for tough industrial jobs, you want something that can handle high pressure and keep working in harsh conditions. fanacdc’s centrifugal fan stands out in these situations. You get high static pressure generation, which means the fan can push air through long ducts or filters. This is perfect for hvac systems, dust collection, and industrial ventilation. The fan works well in environments where you need controlled airflow, like a garage industrial fan or a blower industrial fan setup. You also benefit from low maintenance requirements, so you spend less time worrying about repairs.

- High static pressure generation

- Durability in harsh environments

- Low maintenance requirements

- Effective in ducted systems and environments requiring controlled ventilation

You can trust this fan to deliver reliable performance, even when the job gets tough.

AC Fan Features

When you need a fan for large spaces or continuous cooling, fanacdc’s AC fans are a smart choice. These fans help you save energy, with up to 75% reduction in power consumption. Smart controls let you adjust fan speed based on temperature, so you get efficient cooling without wasting electricity. The fan’s strong airflow makes it ideal for industrial strength fan needs, like cooling machinery or supporting exhaust systems. You also get extended equipment life, which means lower maintenance costs and fewer breakdowns.

| Feature | Benefit |

|---|---|

| Energy Savings | Up to 75% reduction in power consumption |

| Smart Controls | Adjust fan speed based on temperature |

| Maintenance Costs | Extended equipment life reduces costs |

| Carbon Emissions | Lower emissions due to reduced electricity use |

These fans work well in places like factories, server rooms, and anywhere you need reliable cooling.

Customization and Support

Every industrial setup is different. fanacdc gives you options to customize your fan for your exact needs. You can choose the size, voltage, and even the performance curve to match your system. If you work in a tough environment, you can get enhanced protection, like IP-rated designs and corrosion-resistant materials. This keeps your fan running longer, even in harsh conditions.

| Customization Aspect | Details |

|---|---|

| Tailored Size | Custom sizes to fit specific system requirements. |

| Voltage | Options for different voltage requirements to ensure compatibility. |

| Performance Curve | Custom speed curves to match precise performance needs. |

| Adverse Environment Protection | Enhanced protection features like IP-rated designs and corrosion-resistant materials for durability in harsh conditions. |

You also get strong support from fanacdc. The team offers project customization, technical support, sales training, and after-sales service. You can count on help from start to finish, including installation and ongoing maintenance.

| Service Type | Description |

|---|---|

| Project Customization | Professional services to tailor solutions to industrial needs, including requirement evaluation and project management. |

| Technical Support | Comprehensive assistance throughout the project lifecycle, from design to post-installation. |

| Sales Training | Training programs to enhance technical knowledge and customer service skills for partners. |

| After-Sales Service | Ongoing support including 24/7 assistance, repair services, and feedback collection for quality improvement. |

fanacdc’s fans come with strong warranty terms. Most models offer two years on the motor and five years on the blades, so you know your investment is protected.

| Model | Warranty Terms |

|---|---|

| ACDC Rechargeable Fan with Battery Backup | 1 Year |

| Other Models | 2 Years (motor), 5 Years (blades) |

If you want a fan that fits your needs and lasts in tough industrial environments, fanacdc has you covered. Whether you need a centrifugal fan, an axial blade fan, or a solution for industrial ventilation, you’ll find reliable options for every job.

Conclusion

Choosing the right fan for your industrial application can feel overwhelming. You want to make sure you get the best performance, reliability, and value for your investment. When you compare an axial blade fan with a radial fan, you see that each one has its own strengths. Axial fans move a lot of air quickly, making them perfect for open spaces and general ventilation. Radial fans, sometimes called centrifugal fans, handle higher pressure and work well in systems with ducts or filters.

If you need to move air through an exhaust system or push it across long distances, a radial fan might be your best choice. For cooling large rooms or providing steady airflow, an axial fan could be the answer. Think about your space, the airflow you need, and any obstacles the air must pass through. This will help you decide which fan fits your needs.

Here’s a quick checklist to guide your decision:

- Identify your airflow and pressure requirements.

- Consider the layout of your space and any ductwork.

- Think about noise levels and maintenance needs.

- Look for a fan that matches your budget and long-term goals.

Need help? The experts at fanacdc can walk you through every step. They offer a wide range of industrial fans, including options for tough environments and custom solutions. You can count on their support from selection to installation.

Ready to upgrade your ventilation or cooling system? Visit fanacdc’s website or contact their team for advice on the best fan for your project. You’ll get reliable performance, energy savings, and peace of mind for any industrial challenge.

Choosing between an axial blade fan and a radial fan depends on your needs. If you want high airflow in open spaces, axial fans work best. Radial fans, like a centrifugal fan, handle high pressure and tough jobs in places like a garage industrial fan setup. Check out this quick comparison:

| Factor | Axial Fans | Radial Fans |

|---|---|---|

| Efficiency | High airflow, low pressure | High pressure, lower airflow |

| Applications | Home, agriculture, electronics | Industrial, HVAC, dust collection |

| Maintenance | Simple, less upkeep | More complex, regular checks |

| Cost | Lower upfront | Higher for heavy-duty use |

- Axial fans suit industrial strength fan needs in large rooms.

- Radial fans fit blower industrial fan tasks and ducted systems.

You can trust fanacdc for reliable industrial fans for sale. Reach out for expert advice and custom solutions that match your project.

FAQ

What’s the main difference between a radial fan and an axial blade fan?

You’ll notice that a radial fan (or centrifugal fan) pushes air out at a 90-degree angle, which helps with high pressure. An axial blade fan moves air straight through, making it great for high airflow in open spaces.

When should I use a garage industrial fan?

You should use a garage industrial fan when you need strong airflow to cool large garages or workshops. These fans help remove fumes, dust, and heat, keeping your workspace safe and comfortable.

Are industrial strength fans noisy?

Most industrial strength fans, like those from fanacdc, run quietly thanks to advanced motor designs. You might hear some noise at higher speeds, but you can expect reliable performance without too much disruption.

Can I use a centrifugal fan for dust collection?

Absolutely! A centrifugal fan works well for dust collection systems. It creates enough pressure to move air through filters and ducts, making it a top choice for factories and workshops.

Where can I find industrial fans for sale?

You can find industrial fans for sale on the fanacdc website. They offer a wide range of options, including blower industrial fans, radial fans, and axial fans, all designed for tough industrial environments.