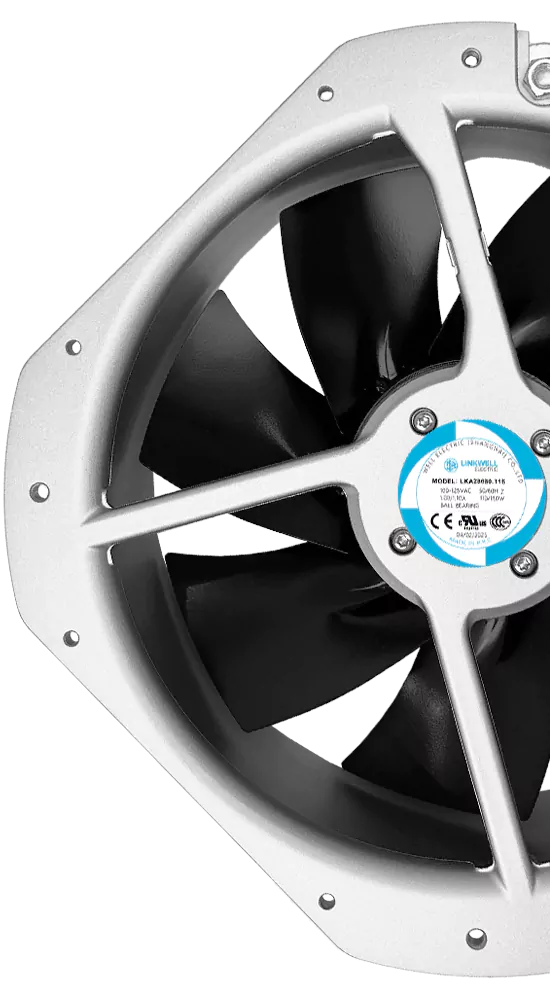

Efficient, quiet, and long-life cooling solutions for industrial & electronics applications

80-280mm

Size Range

12V-48 V

Voltage

–30°C ~ 70°C

Operation Temperature

70,000 hour

Service Life

Fan

Model

Size

(mm)

Voltage

(VAC)

Power

(W)

Speed

(RPM)

Airflow

(CFM)

Brushless motors deliver strong airflow, low power consumption, and long-lasting DC fan reliability.

Optimized blade geometry ensures powerful airflow with quiet operation for sensitive environments.

PWM, tachometer, and alarm functions enable precise speed control and real-time cooling status.

High-grade bearings and thermal engineering provide long operating life under continuous duty.

Our DC fans feature advanced brushless motor technology and precision-balanced rotors to ensure smooth, stable rotation with minimal vibration.

This design reduces mechanical stress, improves airflow consistency, and extends motor life, making them ideal for continuous industrial operation and sensitive electronic systems where reliability matters.

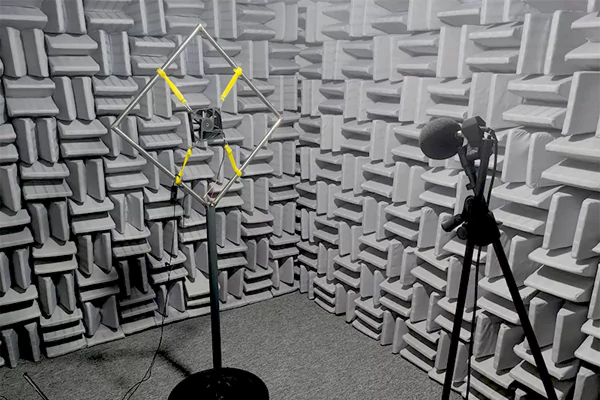

Our aerodynamic blade design and engineering testing process optimize airflow while minimizing noise and energy consumption.

Each fan is verified in lab conditions for noise level, airflow output, and static pressure to ensure consistent performance across production batches, making them suitable for applications requiring efficient, quiet, and dependable cooling.

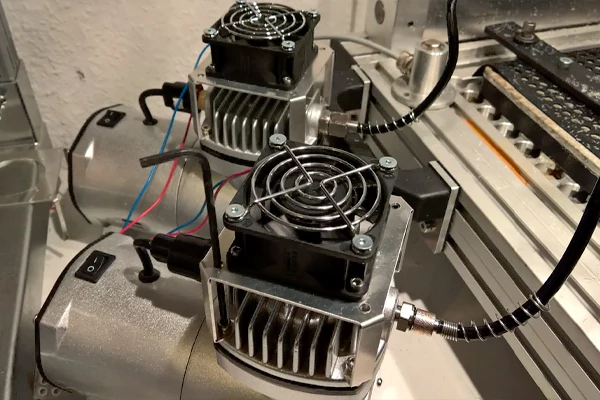

Each DC fan undergoes extensive performance validation, including high-temperature operation, humidity cycling, vibration testing, and extended runtime evaluation.

This rigorous testing process ensures reliable performance in demanding environments, guaranteeing stable cooling for industrial control systems, power electronics, telecommunications equipment, and mission-critical devices.

Ensuring stable airflow for base stations, routers, and network cabinets. Designed for long-hour operation, high ambient temperatures, and consistent cooling performance to protect telecom hardware.

Optimized cooling for battery racks, inverters, and BMS cabinets. Maintains thermal balance, supports high-density energy modules, and enhances safety and longevity in renewable energy storage environments.

Reliable cooling for control cabinets, servo drives, sensors, and production equipment. Built for dusty, continuous-duty environments to ensure stable operation, reduce heat stress, and minimize downtime.

We customize fan dimensions, mounting format, voltage range, airflow direction, and speed curves to fit your system precisely.

Whether your application needs compact footprint, boosted airflow, higher static pressure, or low-noise performance, our engineering team delivers cooling that matches your design and efficiency goals.

For challenging conditions, we provide reinforced designs with dust- and moisture-protection, salt-spray resistance, wide-temperature capability, and extended lifespan components.

These enhancements ensure stable operation in outdoor telecom networks, energy storage systems, industrial equipment, and coastal environments where reliability is critical.

We support fast engineering response, prototype sampling, and flexible production to help you verify thermal design quickly and move to mass production confidently.

From concept testing to urgent supply demand, our streamlined workflow ensures efficient development and stable delivery for time-sensitive projects.

A DC fan is powered by low-voltage direct current (DC), typically 12V, 24V, or 48V, and uses an internal brushless motor system with electronic commutation. Unlike AC fans, which run directly from mains AC power and use induction motors, DC fans allow precise speed control, lower energy consumption, reduced noise, and improved efficiency.

They are ideal for applications where airflow needs to be adjusted dynamically, such as electronics cooling, telecom equipment, new-energy systems, servers, and automation machinery. AC fans are often preferred for high-power, simple ventilation needs in industrial environments, while DC fans excel in environments requiring quiet operation, variable speed, and long life.

In short, DC fans offer greater control, efficiency, and performance flexibility, making them the optimal choice for modern intelligent cooling systems and devices that prioritize energy savings and performance accuracy.

A brushless DC fan motor offers significant advantages in efficiency, reliability, and intelligent control. Unlike brushed motors, it uses electronic commutation, eliminating friction-based wear and allowing smoother, more precise operation. This design delivers higher energy efficiency, lower power consumption, and reduced heat output — critical for modern equipment that requires continuous cooling.

Brushless DC fans are also quieter, with less vibration and improved balance, making them ideal for electronics, telecom, medical, and new-energy applications where acoustic comfort matters. They support advanced control functions such as PWM speed control, tachometer feedback, and alarm output, enabling real-time thermal management and system protection.

With significantly longer service life and excellent performance in harsh industrial environments, brushless DC fans provide stable, dependable cooling and lower total operating costs. These benefits make brushless DC fan motors the preferred choice for high-performance and intelligent cooling applications.

Industrial DC fans typically operate on three standard voltage options: 12V, 24V, and 48V.

Each voltage range supports different application needs:

Choosing the correct voltage depends on your system’s existing power architecture, current limits, safety requirements, and performance needs. Higher voltages reduce current draw, lowering heat and extending equipment life. Our fans support all three voltage levels to provide flexibility for different industries and integrated solutions.

Choosing the right DC fan involves balancing airflow (CFM) and static pressure (mmH₂O or Pa) according to your equipment’s cooling needs. First, determine the heat load and required airflow volume to maintain safe temperature levels in your application. If your system contains dense components, filters, heat sinks, ducts, or restricted airflow channels, a fan with higher static pressure is critical to ensure consistent cooling performance.

We recommend reviewing your equipment ventilation path, operating environment, and temperature thresholds. Our engineering team can provide airflow-curve guidance, simulation support, and fan selection recommendations based on your system’s layout and thermal requirements.

If you need noise control or power savings, we can also recommend speed-adjustable fans to balance cooling and acoustic performance. Proper fan selection ensures optimal heat dissipation, energy efficiency, and long equipment life.

Modern DC fans support multiple smart-control functions to improve cooling efficiency and system protection.

Key control and monitoring signals include:

These intelligent features make DC fans ideal for server racks, telecom equipment, battery storage cabinets, automation systems, and precision-cooling applications. Our products offer stable signal performance and can be customized to match your control-system interface. If your system requires temperature-based control or predictive maintenance features, DC fans with PWM and Tach feedback are the perfect solution.

The service life of a DC fan depends on the bearing type, environment, and operating temperature.

Typical lifespan data is:

Brushless DC fans operate with electronic commutation, meaning fewer mechanical parts wear out over time, resulting in longer life and more stable performance.

For industrial applications, ball-bearing or advanced bearing designs are recommended for extended runtimes, exposure to heat, and vertical mounting scenarios. To maximize lifespan, keep the operating temperature within specification, avoid dust buildup, and ensure proper airflow clearance.

Our DC fans are engineered for long-term stability and tested under industrial-grade reliability standards to ensure dependable performance in demanding applications.

Brushless DC fans require minimal maintenance, thanks to their sealed motor design and lack of mechanical brushes. However, for long-term industrial reliability, periodic checks are recommended.

Key maintenance practices include cleaning dust from blades and filters, ensuring ventilation passages remain unobstructed, and checking fan bearings for noise or vibration over time. In high-dust or corrosive environments, protective filters or sealed designs can help extend service life.

It is also important to monitor fan speed and alarms if supported by your system. By following basic maintenance practices and selecting fans suitable for your environment, you can achieve long, stable operation with minimal downtime.

DC fans generally provide lower noise and reduced electromagnetic interference (EMI) compared with traditional AC fans.

The brushless motor design, smoother commutation, and optimized blade geometry help minimize mechanical vibration and electrical noise. PWM-controlled DC fans can operate at lower speeds under light loads, further reducing noise levels.

Additionally, DC fans generate less EMI due to their low-voltage operation and electronic control systems with built-in filtering and shielding. AC fans may produce more electrical noise because of direct AC power drive and higher motor ripple.

For applications requiring quiet, stable, and interference-free operation—such as telecom racks, server cabinets, medical devices, and precision automation—DC fans are the preferred solution.

WhatsApp us

Curious how LINKWELL’s cooling solutions can address your business challenges? Let’s connect and discuss your needs.