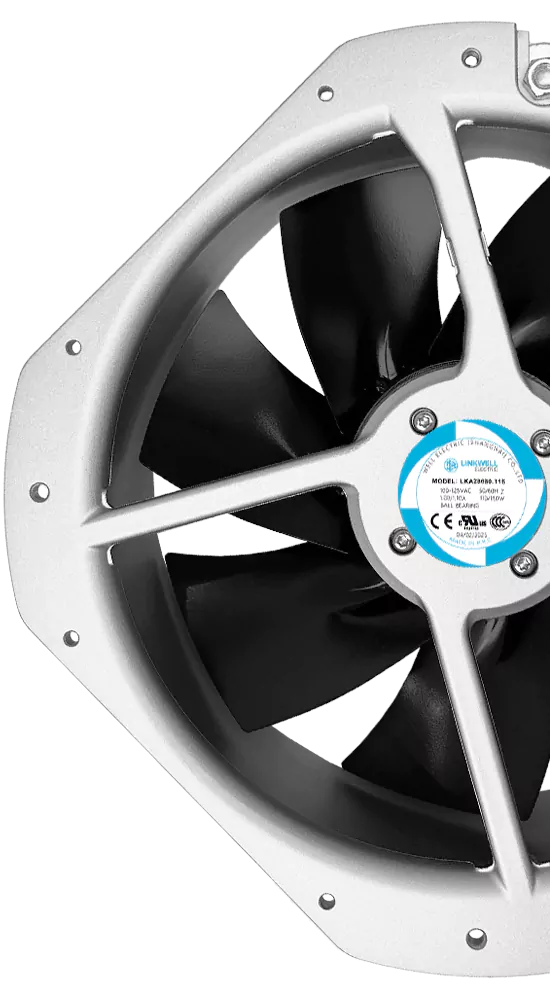

Advanced EC fan motors for energy-saving ventilation, refrigeration, and automation systems.

60-280mm

Size Range

110V / 220V

Voltage

–10°C ~ 70°C

Operation Temperature

2-145W

Power

Fan

Model

Size

(mm)

Voltage

(VAC)

Power

(W)

Speed

(RPM)

Airflow

(CFM)

Designed for modern HVAC and refrigeration systems, our EC fans combine high-efficiency brushless DC motor technology with 110V/220V AC input, delivering powerful airflow and intelligent speed control with standard AC wiring.

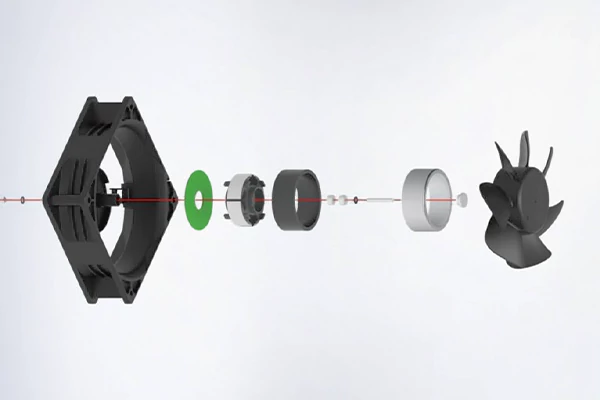

Each EC fan motor integrates an advanced electronic drive, ensuring stable operation, low energy consumption, and extended service life.

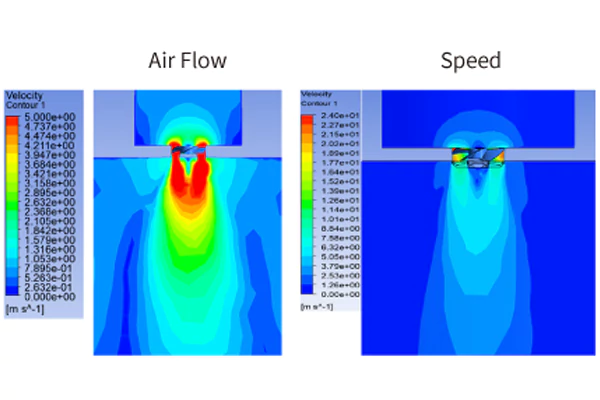

Compared with traditional AC fans, our EC axial fans operate quieter, maintain smoother variable-speed control, and reduce power usage by up to 70%—without requiring external controllers or DC power conversion.

EC technology delivers premium efficiency and precise speed control—while using standard 110V/220V AC power.

Brushless motor design cuts power consumption significantly compared to traditional AC fans.

Supports PWM or analog control for automated airflow adjustment and optimized cooling performance.

Less vibration, smoother rotation, and cooler motor operation extend performance life and reliability.

Integrated controller requires no external drive or DC power supply, simplifying installation and servicing.

Built for refrigeration, HVAC, and industrial equipment with reliable startup and consistent airflow output.

As an experienced EC fan manufacturer, we provide full OEM/ODM engineering support—from product concept and performance design to prototype validation and mass production.

Our team tailors EC axial fans, EC blowers, and EC cooling modules to match airflow demands, life expectancy, acoustic targets, and certification needs.

We ensure every EC fan integrates smoothly into your equipment and delivers long-term, energy-efficient performance.

We engineer EC fans in a wide range of diameters and mounting structures, supporting 110V and 220V AC input with optimized EC motor control. Airflow performance, static pressure, and fan curve can be tuned to match thermal load, space limitations, and system efficiency goals.

Whether you need compact EC axial fan designs or large-format industrial models, we deliver precise performance customization.

Our EC fans and drives offer advanced intelligent control interfaces, including PWM, FG, and RD. These options enable accurate speed regulation, energy management, system diagnostics, and silent-mode operation.

Integration with BMS and industrial control systems ensures optimized performance and reduced energy consumption across refrigeration units, ventilation systems, and automated equipment.

Used in air purifiers, filtration units, and environmental control systems, EC fans deliver low-noise airflow, stable speed regulation, and exceptional efficiency for clean-air performance.

EC axial fans deliver consistent airflow and high efficiency for supermarket freezers, display coolers, and cold rooms—ensuring stable temperatures, reduced energy bills, and quieter operation.

EC cooling fans protect sensitive electronics in automation cabinets, inverters, and server enclosures by providing efficient thermal management and precise airflow performance under continuous operation.

EC (Electronically Commutated) fans combine AC and DC technologies, featuring a brushless DC motor with integrated electronics that allow precise control and high efficiency.

While powered by standard AC mains (110V/220V), the internal circuitry converts AC to DC, enabling advanced motor control through electronic commutation. This results in smoother operation, variable speed control, and reduced energy loss. EC fans are widely used in HVAC, refrigeration, telecommunications, and cleanroom applications where stable airflow and energy efficiency are critical. Their compact design and built-in control logic make them ideal for smart, automated environments.

EC fans are significantly more energy-efficient than traditional AC fans, often reducing power consumption by up to 75%.

This efficiency is achieved through electronically controlled brushless motors that adjust speed precisely according to demand. Unlike AC fans that run at constant speed, EC fans vary output dynamically, lowering energy waste during low-load conditions.

They also produce less heat, improving system performance and lifespan. Over time, the reduced energy usage and lower maintenance requirements result in substantial cost savings, making EC technology an ideal choice for sustainable and energy-conscious applications in HVAC, data centers, and industrial cooling systems.

Yes, EC fans can often replace conventional AC fans with minimal modification, but certain considerations are essential. The physical dimensions, airflow direction, and mounting design should match existing equipment. EC fans operate on AC input voltage (110V or 220V) but integrate electronic control circuits, which may require compatibility checks for control signals like PWM or FG.

Retrofitting provides immediate benefits in energy efficiency, speed control, and noise reduction, but installation should be done by a qualified technician to ensure proper wiring and optimal performance. When retrofitted correctly, EC fans significantly enhance reliability, reduce energy consumption, and extend system service life.

Modern EC fans support multiple intelligent control interfaces such as PWM (Pulse Width Modulation) for variable speed control, FG (Frequency Generator) for tachometer signal feedback, and RD (Rotation Detection) for operational monitoring.

These functions enable smart integration with building management systems or industrial automation platforms. PWM signals allow precise airflow adjustment to match cooling demand, reducing energy consumption. FG outputs provide real-time speed feedback, while RD alerts users to fan failure or abnormal operation. Together, these advanced control features make EC fans ideal for smart HVAC, data center, and industrial applications where efficiency, monitoring, and reliability are crucial.

EC fans require minimal maintenance due to their brushless motor design, which eliminates the wear and dust associated with mechanical commutation. The integrated electronics provide smoother operation, reducing vibration and bearing stress.

Unlike AC fans, EC models don’t require regular brush replacement or lubrication beyond standard periodic cleaning. They also feature built-in protection circuits against over-voltage, over-temperature, and overload conditions, further extending service life.

With fewer moving parts and intelligent monitoring functions, EC fans deliver long-term reliability and lower total maintenance costs, making them ideal for applications where downtime and service interruptions must be minimized.

EC fans are designed for low-noise operation thanks to precise electronic commutation, aerodynamic blade design, and optimized motor balance.

Unlike conventional AC fans, EC motors eliminate mechanical switching noise and reduce torque ripple, resulting in smoother airflow and lower vibration. Linkwell’s EC fans also use high-quality ball bearings and advanced housing materials that minimize resonance and acoustic emissions. Intelligent speed control further allows quiet operation under partial load, where less airflow is needed.

These features make EC fans ideal for environments requiring both performance and low noise—such as data centers, laboratories, hospitals, and commercial refrigeration systems.

WhatsApp us

Curious how LINKWELL’s cooling solutions can address your business challenges? Let’s connect and discuss your needs.