Electrical Enclosures

Electrical Enclosure Cooling

Electrical enclosures act as the control core of industrial systems, yet excessive heat remains a major cause of equipment failure and costly downtime. Studies show that nearly one-third of electrical cabinets face overheating risks, leading to reduced efficiency, system instability, and potential financial loss due to unplanned outages.

Key challenges we solve:

- Prevent Overheating: Maintain enclosure temperatures below 35 °C (95 °F) to protect sensitive components and extend service life.

- Protect Against Dust & Moisture: Our cooling fans support sealed designs that prevent contaminants from entering critical electrical areas.

- Reduce Energy Consumption: High-efficiency fan systems deliver optimized cooling while minimizing energy use and operational expenses.

LinkWell’s enclosure cooling fans are engineered for reliability, ensuring steady thermal management, maximum uptime, and long-term operational stability.

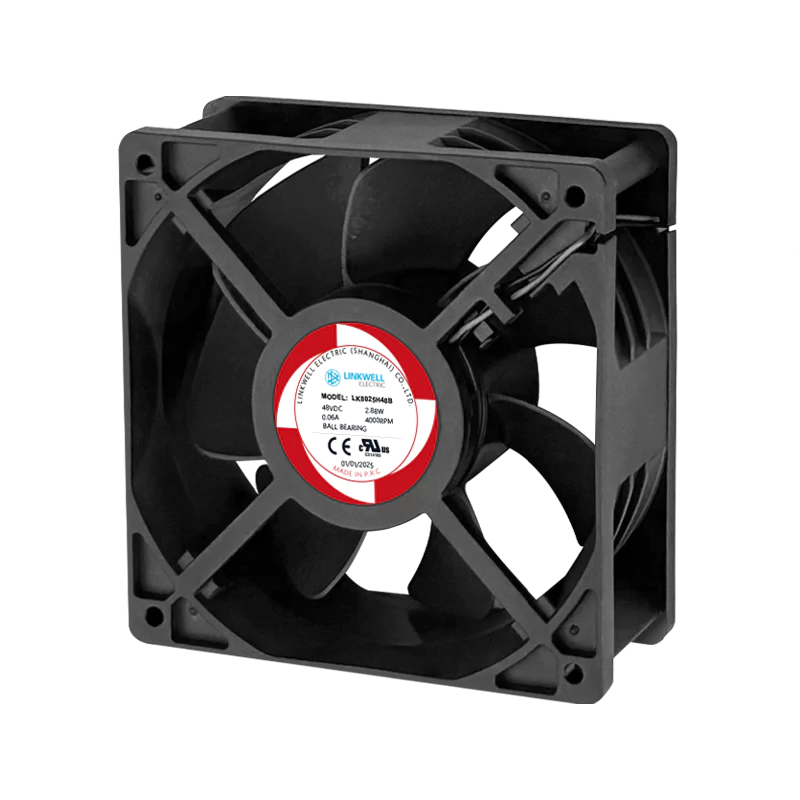

We Match Enclosure Fans to Your Specific Applications

At LinkWell, our enclosure fans are engineered for efficient airflow and heat control across industrial environments. Built for durability and high performance, they deliver reliable cooling solutions—whether your application requires high static pressure or large-volume airflow.

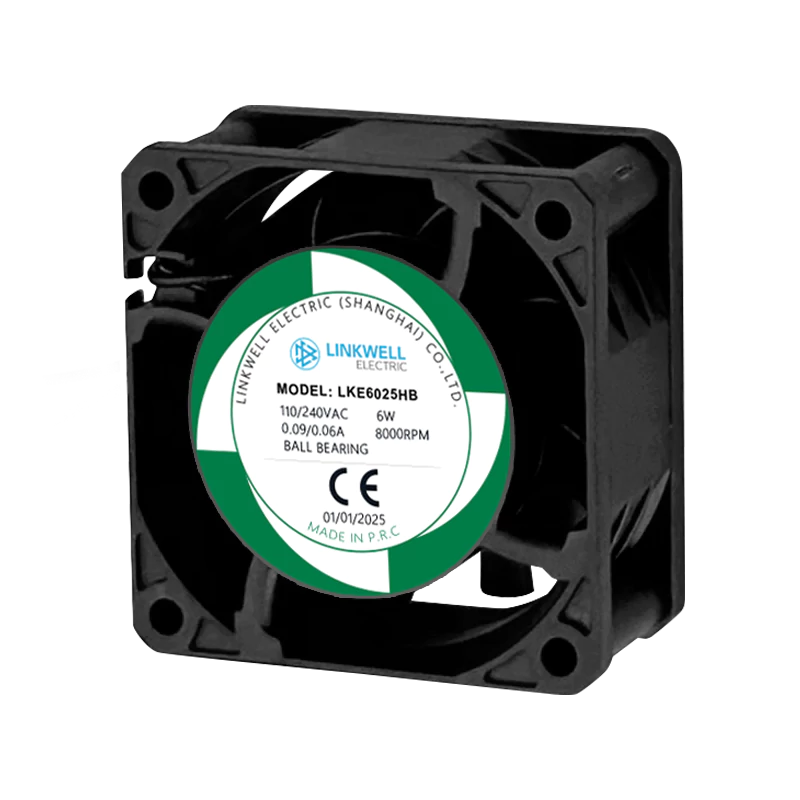

Small Junction Boxes

Small junction boxes protect essential electrical connections, but their compact size often traps heat that threatens component stability. LinkWell provides compact, high-efficiency cooling solutions to maintain consistent performance and extend equipment lifespan.

- Compact Cooling: Our miniature fans—available in 60mm and 70mm sizes—offer strong airflow even in tight spaces, ensuring effective heat dissipation.

- Low-Voltage Compatibility: Supporting 12V and 24V DC input, our fans integrate seamlessly with standard low-voltage junction box systems.

- Long-Term Reliability: Engineered for maintenance-free operation, LinkWell fans achieve up to 70,000 hours of service life and can be customized with IP68 protection for demanding industrial environments.

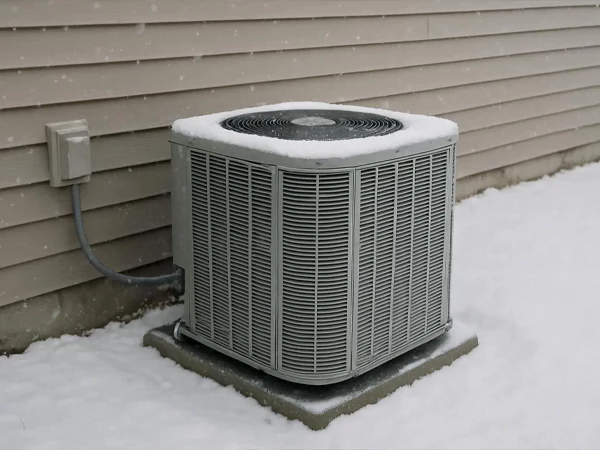

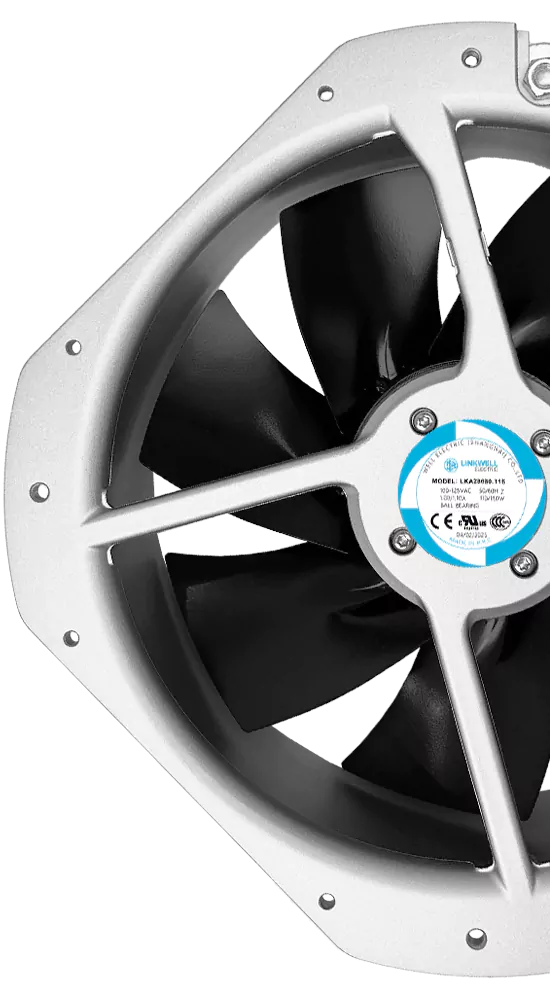

Large Outdoor Integrated Cabinets & Shelters

Outdoor cabinets operate under extreme conditions, combining high internal heat with challenging environments. LinkWell provides robust and efficient cooling solutions designed for long-term reliability and system protection.

- High-Performance Airflow: Effectively manages heavy heat loads with high-volume AC fans (up to 1003 CFM), energy-efficient DC fans, and smart EC fans with PWM control for optimized energy use.

- Weatherproof Durability: Features IP68-rated DC fans and anti-salt spray coated AC fans for reliable performance in all climates.

- Comprehensive Protection: Paired with filter units to create a sealed cooling system that blocks dust and moisture, ensuring clean, stable operation.

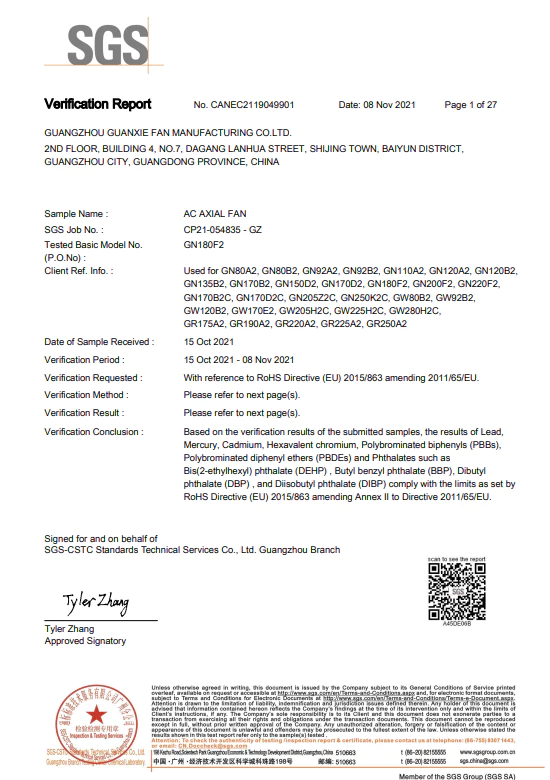

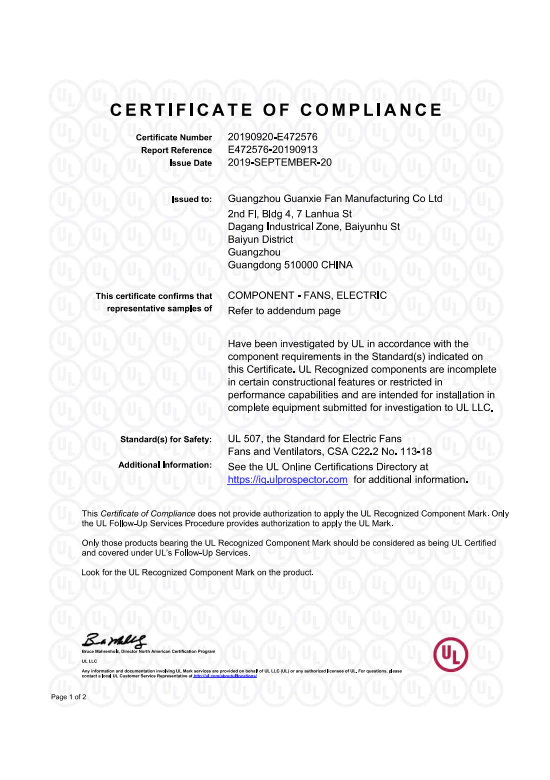

Why Choose Our Enclosure Cooling Systems

Your enclosure’s uptime is only as good as its cooling. Our systems ensure maximum uptime, protecting sensitive components from heat, airborne contaminants, and extreme environments. Globally certified and rigorously tested, our solutions provide proven protection for your critical equipment.

Each LinkWell enclosure cooling fan is engineered for longevity, delivering up to 70,000 hours of continuous operation. This ensures long-term reliability, reduced maintenance, and lower total ownership costs.

Built from industrial-grade materials with enhanced thermal stability and flame-retardant components, our fans maintain structural integrity under high temperatures and demanding environments.

Integrated with PWM control technology, LinkWell fans automatically adjust airflow based on system temperature—optimizing cooling performance while minimizing power consumption and noise.

Tested for high-altitude, outdoor, and dusty environments, LinkWell cooling systems deliver consistent performance and protection, ensuring uninterrupted operation of sensitive electrical equipment.

Need a Custom Enclosure Cooling Solution?

At LinkWell, we design custom cooling solutions — from individual fans to full enclosure systems — ensuring reliable, efficient performance for your specific application.

AC Fans

DC Fans

High-speed brushless fans up to 8,000 RPM, offering efficient, stable, and energy-saving cooling.

EC Fans

Energy-saving fans using 75% less power, ensuring reliable performance and reduced operating costs.

Centrifugal Fan

Compact high-pressure fans up to 300 Pa, ideal for efficient airflow in confined spaces.

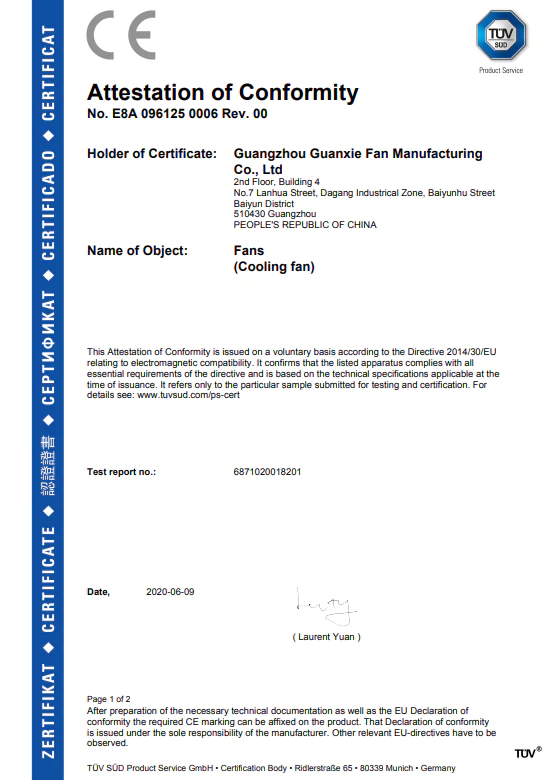

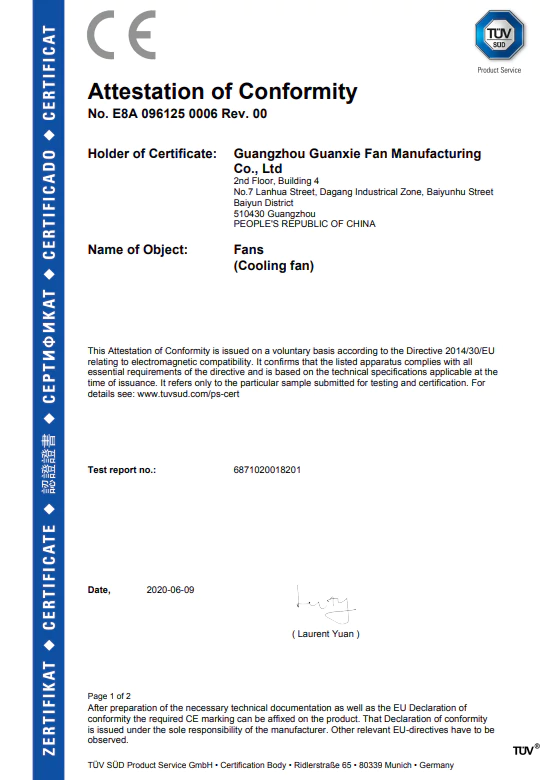

Certificates

FAQs

What is an electrical enclosure cooling system and why is it necessary?

An electrical enclosure cooling system is designed to regulate temperature inside cabinets or control panels that house sensitive electronic components. Excessive heat buildup can cause premature component failure, reduced efficiency, or even complete system shutdown.

By maintaining a stable internal temperature, enclosure cooling fans or systems help extend equipment lifespan, ensure reliable operation, and reduce unplanned downtime.

For industrial applications where electronics are densely packed, proper thermal management is essential to meet safety standards and prevent costly production interruptions.

How do I determine the right fan size and airflow for my electrical enclosure?

Selecting the correct fan size and airflow (CFM) depends on the enclosure’s dimensions, the amount of heat generated by internal components, and the desired internal temperature.

First, calculate the heat load in watts and determine how much airflow is required to dissipate that heat efficiently.

Other factors such as enclosure material, ambient temperature, and installation location also influence airflow requirements. LinkWell provide thermal calculation tools and engineering support to help you choose the right configuration for optimal performance.

What are the main types of cooling fans used in electrical enclosures?

Electrical enclosures commonly use AC, DC, and EC fans, each suited to different needs. AC fans are reliable, durable, and ideal for general industrial use. DC fans offer precise speed control, lower noise, and improved energy efficiency. EC fans combine the best of both worlds, using brushless DC motors with AC input to achieve up to 70% energy savings and smart control features like PWM and tachometer signals. Choosing the right fan depends on your project’s voltage, efficiency goals, and control requirements.

How does IP rating affect the performance of an enclosure cooling fan?

The IP (Ingress Protection) rating defines how well a cooling fan resists dust and water intrusion. For electrical enclosures, a higher IP rating—such as IP55, IP67, or IP68—is crucial for ensuring reliability in harsh environments. Fans with high IP ratings are sealed to prevent moisture, oil mist, or fine dust from entering the motor or bearings, reducing the risk of corrosion and extending operational life. Selecting an appropriate IP rating helps maintain performance stability, especially for outdoor, industrial, or coastal applications.

What are the common causes of overheating inside electrical enclosures?

Overheating in electrical enclosures is typically caused by inadequate ventilation, poor component layout, or excessive ambient temperature.

Dust accumulation, high humidity, and blocked air paths can also restrict airflow and trap heat inside.

Additionally, high-density power electronics or inverters generate more heat than natural convection can handle.

Installing correctly sized cooling fans or heat exchangers, maintaining filter cleanliness, and ensuring unobstructed airflow paths are essential measures to prevent thermal buildup and protect system integrity.

How can I improve energy efficiency in my electrical cabinet cooling system?

Energy efficiency can be improved through the use of EC (electronically commutated) fans, which adjust their speed based on thermal demand and consume up to 70% less power than traditional AC fans.

Implementing smart control options like PWM speed regulation or thermostat-based operation also reduces unnecessary energy use.

Additionally, using optimized airflow design, efficient filters, and low-resistance ventilation paths can significantly enhance performance while lowering overall operating costs.

What maintenance practices extend the lifespan of enclosure cooling fans?

To extend the life of enclosure cooling fans, perform regular inspections to check for dust buildup, bearing noise, and vibration. Clean filters and fan blades periodically to ensure unobstructed airflow. Verify that all electrical connections remain secure, and replace worn gaskets to maintain IP protection.

Using fans with sealed ball bearings, IP-rated enclosures, or automatic speed control can further reduce wear and extend service life—sometimes up to 70,000 hours of continuous operation.

Can enclosure fans be customized for specific environments such as high humidity or outdoor use?

Yes, enclosure fans can be customized to meet the demands of unique environments. For outdoor or high-humidity conditions, manufacturers can apply anti-corrosion coatings, IP68 waterproof sealing, or salt-spray-resistant materials.

Fans used in high-temperature areas can feature heat-resistant plastics, reinforced bearings, and specialized motor designs. Custom voltage options, airflow ratings, and control interfaces can also be tailored to fit specific project needs.

At LinkWell, we provide OEM/ODM customization to ensure reliable performance in any application environment.