You want your industrial cooling fans to work at their best, right? Start by picking the right fan for your space—AC, DC, EC, or centrifugal. Place each fan where it can move air efficiently over equipment or work areas. Regularly check and clean your cooling fans so dust and debris don’t slow them down. When you optimize your fan setup, you can see energy savings of up to 30% in large spaces. For maximum efficiency, always match your fan type to the job and stay on top of maintenance. You’ll get the most from your industrial fans and blowers, and your cooling will stay reliable.

- How to use industrial cooling fans for top results:

- Choose the best fan type for your needs.

- Install fans in the right locations.

- Keep up with routine maintenance.

Key Takeaways

- Choose the right fan type for your needs to ensure optimal cooling performance.

- Install fans in strategic locations to maximize airflow and protect equipment from heat damage.

- Regularly maintain your fans by cleaning and inspecting them to prevent breakdowns and extend their lifespan.

- Utilize smart speed controls to balance cooling needs with energy efficiency, reducing power consumption.

- Monitor fan performance and address any issues early to maintain maximum efficiency and reliability.

How Does a Cooling Fan Work in Industrial Settings

Principles of Industrial Cooling Fans

You might wonder, how does a cooling fan work in your factory or workshop? Industrial cooling fans use thermodynamic principles to move heat away from equipment and workspaces. The fan blades create a pressure difference, pulling in cooler air and pushing out warmer air. This ongoing airflow keeps temperatures steady and helps with process cooling. You get the best results when you choose the right fan type—AC, DC, EC, or centrifugal—for your needs. Blade design, motor speed, and proper placement all play a big part in how well your fan performs.

- Here’s what happens when you use industrial cooling fans:

- The fan draws in fresh air and expels hot air.

- Airflow replaces heated air with cooler air, making the chilling effect stronger.

- You keep your machines and people comfortable and safe.

Heat Dissipation and Airflow Mechanisms

Let’s dig deeper into how does a cooling fan work for heat dissipation. Industrial cooling fans play a key role in process cooling by circulating air and removing excess heat. This is vital for cooling of machineries and keeping everything running smoothly. Centrifugal fans, for example, deliver strong airflow to various processes and help lower temperatures between critical stages. You can count on these fans to regulate temperature and prevent hotspots. Forced convection moves air across hot surfaces, which means your equipment stays cool and reliable.

Tip: Place your fan near heat sources or where airflow is blocked. This boosts cooling and prevents overheating.

Benefits for Equipment and Personnel

You get a lot of uses and benefits from industrial fans and blowers. They protect sensitive equipment, improve energy efficiency, and make your workplace safer. Check out this table to see how does a cooling fan work to help you and your team:

| Benefit | Description |

|---|---|

| Temperature Stability | Keeps equipment safe and reduces the risk of shutdown or damage. |

| Improved Energy Efficiency | Motors and drives work better at the right temperature. |

| Extended Equipment Life | Less overheating means lower maintenance costs and longer life. |

| Safe Work Environment | Cooler air makes workers more comfortable and safe in hot areas. |

Industrial cooling fans also help with process cooling in manufacturing plants. They keep temperature-sensitive inventory safe and maintain the right environment. When you use industrial fans and blowers, you get better air quality, fewer heat-related illnesses, and higher productivity. Improved airflow means your team can focus, make fewer mistakes, and stay healthy.

Selecting the Right Industrial Cooling Fan from fanacdc

AC, DC, EC, and Centrifugal Fan Types

You have a lot of choices when it comes to industrial cooling fans. At fanacdc, you can pick from AC, DC, EC, and centrifugal fans, all with diameters between 80mm and 335mm. You won’t find any fans over 400mm here, so you know you’re getting the right size for most industrial setups.

Here’s a quick look at how each fan type stacks up:

| Fan Type | Energy Consumption | Performance Characteristics |

|---|---|---|

| AC | Higher electricity usage | High output power, steady torque, reliable under changing loads |

| DC | More energy efficient | Lower output, great control at low speeds, needs a controller |

| EC | High energy saving | Super efficient, quiet, precise speed and air volume control, long life |

| Centrifugal | Depends on design | High static pressure, great for ducted or obstructed spaces |

You can use these high-performance air-moving devices for everything from cooling electronics to keeping air fresh in workspaces.

Key Selection Criteria (Size, Airflow, Static Pressure)

Choosing the right fan means looking at more than just the type. You need to match the fan’s size, airflow, and static pressure to your application. Here’s what you should check:

| Factor | Description |

|---|---|

| Air Flow (CFM) | How much air the fan moves. More airflow means better cooling. |

| Static Air Pressure | Important for enclosed or ducted spaces. Higher pressure helps push air through obstacles. |

| Fan Speed (RPM) | Faster fans cool more but can be noisier. |

| Heat Generation | Figure out how much heat your equipment makes. |

| Device Specs | Know the ideal temperature for your machines. |

| Multi-fan Setups | Sometimes you need more than one fan for even cooling. |

Tip: In open spaces, airflow is highest. If you have a closed or blocked area, you’ll need a fan with higher static pressure to keep air moving.

Customization and OEM/ODM Options

You might need something special for your project. fanacdc offers lots of ways to customize industrial fans and blowers:

| Customization Feature | Description |

|---|---|

| Logo Placement | Put your logo on the blade hub or grille |

| Color Customization | Pick the color that fits your brand |

| Branded Packaging | Get custom packaging for your orders |

| Voltage Ranges | Choose the voltage you need |

| Speed Control Options | Set up fans for different speed settings |

| Protection Levels | Get fans with the right IP rating for tough environments |

| Adapter Adaptation | Make sure your fan fits your system |

You can even get CAD-assisted engineering support to turn your ideas into real, production-ready fans. For most customizations, you only need a minimum order of 100 sets.

If you want industrial cooling fans that fit your exact needs, fanacdc has you covered.

How to Use Industrial Cooling Fans for Maximum Efficiency

Installation and Placement Best Practices

You want to get the most out of your industrial cooling fans, right? Start with smart installation. The way you set up your fans can make or break your cooling efficiency. Here’s how to use industrial cooling fans for the best results:

- Assess your workspace. Walk around and look for hot spots or areas with poor airflow. Each section of your warehouse or factory might need a different approach.

- Place fans where they can move air across equipment and work zones. Good placement boosts employee comfort and protects goods from heat damage.

- Think about height. Mount fans at the right level to enhance air movement and keep the air fresh for everyone.

- Secure each fan tightly. Use the right mounting hardware to prevent vibrations and noise. A stable fan means quieter operation and less wear.

- Connect fans to your existing electrical system. This keeps energy efficiency high and avoids unnecessary power loss.

- Always follow the manufacturer’s guidelines. Safe installation matters, especially in hazardous environments. Make sure only qualified personnel handle the setup.

Tip: Strategic fan placement can improve airflow, regulate temperature, and even increase productivity. Don’t just guess—plan your layout for optimal fan performance.

Speed Control and Energy Management

Now, let’s talk about how to use industrial cooling fans to save energy without losing cooling power. You don’t need to run your fans at full speed all the time. Smart speed control can make a huge difference in energy efficiency and noise levels.

- Reduce fan speed by 25%. You’ll see up to 60% less power use and a noticeable drop in noise—about 6 decibels. Just remember, airflow will also decrease by 25%, so balance speed with your cooling needs.

- Use variable frequency drives (VFDs). These let you adjust fan speed based on real-time cooling demand. VFDs cut energy use by matching motor speed to what your process actually needs, not just running at max all day.

- Try thermal speed control. Some fans use a thermistor to sense temperature and adjust speed automatically. When things cool down, the fan slows, saving energy and reducing noise.

- Set up a control system with sensors. Monitor pressure or airflow and let the system adjust fan speeds for you. This keeps cooling fan operation efficient and responsive.

- If you have older fans, consider retrofitting them with VFDs. Even a small speed reduction can lead to big energy savings over time.

Note: Combining central air conditioning with portable fans or misting units can target cooling where you need it most, making your whole system more efficient.

Monitoring and Maintenance Tips

You can’t have maximum efficiency without regular checks and upkeep. Here’s how to use industrial cooling fans to keep your system running smoothly year-round:

- Clean surface dust and listen for odd noises every day.

- Once a week, clean the blades and tighten any loose fasteners.

- Each month, lubricate moving parts and inspect all electrical connections.

- Do a deep clean and check the motor and capacitor at least once a year. Replace any worn-out parts before they cause trouble.

- In dusty areas, bump up your cleaning schedule to once a month. In cleaner spaces, quarterly maintenance might be enough.

Keep an eye on these signs:

- Vibration levels—imbalanced blades or worn bearings can cause problems.

- Temperature changes—overheating may mean airflow is blocked or the motor is overloaded.

- Noise patterns—new or loud sounds often signal mechanical wear or loose parts.

- Energy consumption—unexpected spikes can point to blockages or fan wear.

Here’s a quick table to help you troubleshoot common issues:

| Problem Type | What to Do |

|---|---|

| Reduced Airflow | Clean inlets, check for damaged or dirty blades, replace if needed |

| Unusual Noise | Lubricate or replace bearings |

| Overheating | Check belt tension, maintain the motor, call a technician if needed |

| Vibration/Imbalance | Tighten loose parts, ensure stable mounting, balance the fan |

| Motor Overheating | Improve ventilation, check motor load, replace if necessary |

| Inadequate Exhaust | Clean ducts, inspect the motor |

| Excessive Noise | Lubricate bearings, tighten components |

| Airflow Obstruction | Clean blades, remove debris |

| Fan Unbalance | Secure all parts, balance the fan |

Cleaning fan blades and housings can boost cooling efficiency by up to 20%. Regular maintenance also extends the life of your fans and prevents costly breakdowns.

For the best results, use predictive maintenance tools. Smart sensors can monitor vibration, temperature, and airflow in real time. They alert you to problems before they get serious. Remote monitoring lets you check your system from anywhere, so you can act fast if something goes wrong.

Train your team on proper cooling fan operation and maintenance. Well-trained staff spot issues early and keep everything running at peak performance.

If you follow these steps, you’ll know exactly how to use industrial cooling fans for maximum efficiency. You’ll enjoy better airflow, lower energy bills, and longer-lasting equipment. That’s a win for your process and your bottom line.

Conclusion

You’ve now got the tools to get the most out of your industrial cooling fans. When you choose the right fan type—AC, DC, EC, or centrifugal—you set yourself up for success. Smart installation, regular maintenance, and energy management keep your system running strong. You don’t just save money on energy bills. You also protect your equipment and create a safer, more comfortable workspace.

Let’s recap the key steps for maximum efficiency:

- Pick the right fan for your needs. Match airflow, static pressure, and size to your application.

- Install fans in the best spots. Place them where they can move air over hot equipment and work zones.

- Control fan speed. Use smart controls to balance cooling and energy use.

- Stay on top of maintenance. Clean, inspect, and listen for changes so you catch problems early.

Tip: Even small changes—like cleaning blades or adjusting speed—can boost efficiency and extend fan life.

You can trust fanacdc’s industrial cooling fans for reliable performance. The fans come in sizes from 80mm to 335mm, so you’ll find the perfect fit for your setup. You get advanced engineering, energy savings, and options for customization. Whether you need AC fans for durability, DC fans for precise control, EC fans for energy savings, or centrifugal fans for high static pressure, fanacdc has you covered.

Ready to upgrade your cooling system? Take a look at your current setup. See where you can improve airflow, cut energy costs, or add smarter controls. If you want a custom solution or need technical support, fanacdc’s team is here to help.

Visit fanacdc’s official website for more info or to get started!

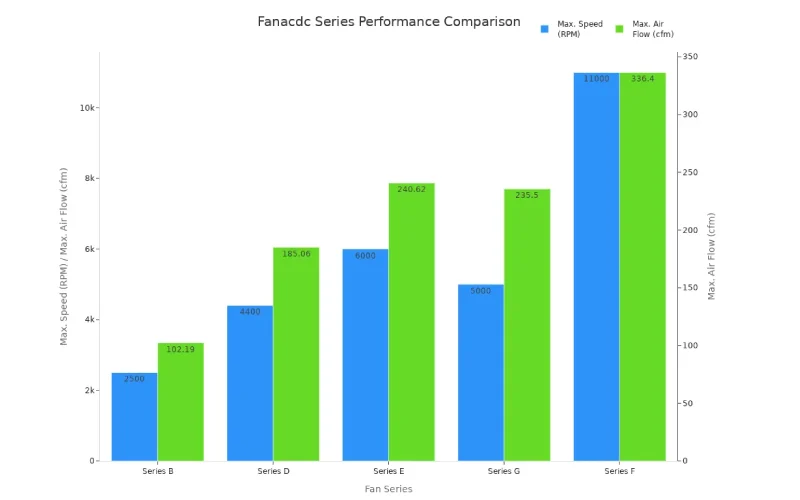

You can boost your cooling system’s efficiency by choosing the right fan, installing it smartly, and keeping up with maintenance. Upgrading to fanacdc’s industrial cooling fans means you get top energy savings, less downtime, and smarter controls. Check out how our models stack up:

| Series | Voltage | Max. Speed | Max. Air Flow | Highest IP |

|---|---|---|---|---|

| B | 12V/24V | 2500RPM | 102.19cfm | IP55 |

| D | 12V/24V/48V | 4400RPM | 185.06cfm | IP56 |

| E | 12V/24V/48V | 6000RPM | 240.62cfm | IP68 |

| G | 12V/24V/48V | 5000RPM | 235.50cfm | IP68 |

| F | 24V/48V | 11000RPM | 336.40cfm | IP68 |

You’ll find expert support, project customization, and after-sales service on the fanacdc website. Take a look at your setup and see how you can upgrade today!

FAQ

What types of industrial cooling fans can you choose from at fanacdc?

You can pick AC fans, DC fans, EC fans, or centrifugal fans. Each type fits different cooling needs. Sizes range from 80mm to 335mm. You get options for energy savings, speed control, and high airflow.

How do you know which fan size is right for your space?

Check your equipment’s cooling needs and the area you want to cover. Match the fan’s airflow and static pressure to your setup. If you’re unsure, ask fanacdc’s team for help.

Can you customize your industrial cooling fan order?

Yes! You can choose voltage, speed control, color, logo placement, and protection level. fanacdc offers OEM and ODM services. You get a fan that fits your exact requirements.

How often should you clean and maintain your cooling fans?

Clean blades and housings every week. Inspect for loose parts and odd noises. Lubricate moving parts monthly. Regular maintenance keeps your fans running smoothly and extends their life.