You want to start optimizing industrial ac cooling fans for maximum efficiency right now. Choose fan types that fit your application—axial for open spaces, centrifugal for high-pressure spots. Match the voltage and frequency to your equipment. Use strategies like advanced control systems and precise sizing to cut energy use by up to 20%. Check out the table below for quick energy-saving stats and see how brands like fanacdc offer project customization and technical support to boost cooling efficiency.

| Aspect | Statistic/Trend |

|---|---|

| Energy Savings | 15–20% energy savings from 2022 to 2025 |

| Government Regulations | New energy efficiency standards (SEER, EER) |

| Market Dynamics | More renewable-integrated HVAC solutions |

Key Takeaways

- Choose the right fan type for your application. Axial fans work well in open spaces, while centrifugal fans are better for high-pressure areas.

- Match voltage and frequency to your equipment. This ensures optimal performance and energy efficiency.

- Use advanced controls like variable frequency drives to adjust fan speed. This can reduce energy consumption and extend equipment life.

- Regular maintenance is key. Set up a schedule to check fan components and use sensors for monitoring performance.

- Consider custom fan solutions for unique needs. Custom options can provide better efficiency and fit specific requirements.

Key Factors in Optimizing Industrial AC Cooling Fans

Fan Type and Application Needs

You want your cooling system to run smoothly and last for years. Careful selection of fan type makes a big difference in industrial settings. Axial fans work best for high-volume, low-pressure jobs, but they can be noisier. Centrifugal fans handle high-pressure and dusty environments, offering a longer lifespan. HVLS fans cover large areas and boost energy efficiency. Check out this table to see how each fan type fits different needs:

| Fan Type | Best For | Lifespan Potential |

|---|---|---|

| Axial fan | High volume, low pressure | 5–10 years |

| Centrifugal fan | High pressure, dusty environments | 8–15 years |

| HVLS fan | Large areas, energy efficiency | 10–20 years |

Don’t just focus on size. Think about noise, airflow, and how long you need the fan to last. Fanacdc offers a full range of industrial fans, including AC, DC, EC, and centrifugal models, so you can match the right fan to your application.

Voltage, Frequency, and Motor Technology

Matching voltage and frequency to your motors is key for top efficiency. North America uses 60 Hz and 230V or 460V, while Europe and Asia use 50 Hz and 400V. If you use the wrong frequency, your motor’s horsepower drops, and performance suffers. Energy-efficient motors paired with variable frequency drives (VFDs) let you control speed and airflow, cutting energy waste. You get better energy efficiency and more reliable performance. Fanacdc’s engineering-driven solutions support advanced motor control, so you can optimize your industrial cooling setup.

Airflow and Static Pressure Considerations

Airflow and static pressure matter just as much as size. High airflow works best in open spaces, while high static pressure is needed for environments with filters or tight ducts. Here’s a quick look:

| Fan Type | Best Use Case | Key Characteristics |

|---|---|---|

| Static Pressure | High resistance (filters, ducts) | Generates pressure for airflow; quieter; limited volume |

| Airflow | Open areas, rapid air movement | Maximizes air volume; lower pressure; swift circulation |

High-density air improves heat dissipation and cooling efficiency. Low-density air reduces performance. Fanacdc uses advanced impeller design and assembly configuration to maximize airflow and energy efficiency, so your industrial fans deliver the best results.

Fan Selection and Sizing for Maximum Efficiency

Matching Airflow and Static Pressure

You want your industrial cooling fans to deliver the right amount of air at the right pressure. Start by figuring out how much heat your equipment produces. Calculate the airflow needed to keep temperatures in check. If you have enclosed cabinets, you need fans that can push air through filters and tight spaces. Open chassis setups need fans that move air quickly across components.

Here’s a simple way to approach correct fan sizing for industrial environments:

- Measure the heat generated inside your device.

- Decide on the ideal operating temperature.

- Calculate the airflow required based on heat and ambient temperature.

- Check the static pressure needed to overcome filters or ducts.

- Pick a fan that matches both airflow and static pressure.

- Consider using multiple fans in parallel or series for better cooling.

Tip: Balancing airflow and static pressure helps you avoid hot spots and keeps your equipment running smoothly.

Choosing the Right Size and Structure

Fan size matters more than you might think. If you pick a fan that’s too small, it won’t cool your industrial equipment properly. If you go too big, you waste energy and space. Correct fan sizing means matching the fan’s dimensions to your installation space, noise limits, and airflow needs.

Take a look at how different fan sizes impact your setup:

| Fan Size | Airflow Impact | Noise Levels | Installation Space |

|---|---|---|---|

| 120mm | Moderate | Moderate | Fits in tight spaces |

| 140mm | High | Low | Fits in most setups |

| Larger | Very High | Low | Requires more space |

If you work with control cabinets or server racks, a 120mm fan often fits best. For bigger industrial machines, you might need a 140mm or larger fan. Larger fans usually run quieter and move more air, but they need more room. Always check your available space before you decide.

Choosing the right structure also matters. Axial fans fit tight spaces and work well for general cooling. Centrifugal fans handle higher pressure and work better in ducted systems. When you get correct fan sizing, you save energy, reduce noise, and extend the life of your equipment.

| Evidence Type | Description |

|---|---|

| Energy Efficiency | Properly sized systems operate efficiently, reducing wasted energy and lowering electricity usage. |

| Component Longevity | Systems that are not overworked experience less wear and tear, leading to fewer repairs and longer lifespans. |

| Temperature Control | Consistent temperature regulation across zones enhances comfort and contributes to energy savings. |

Axial vs. Centrifugal Fans from fanacdc

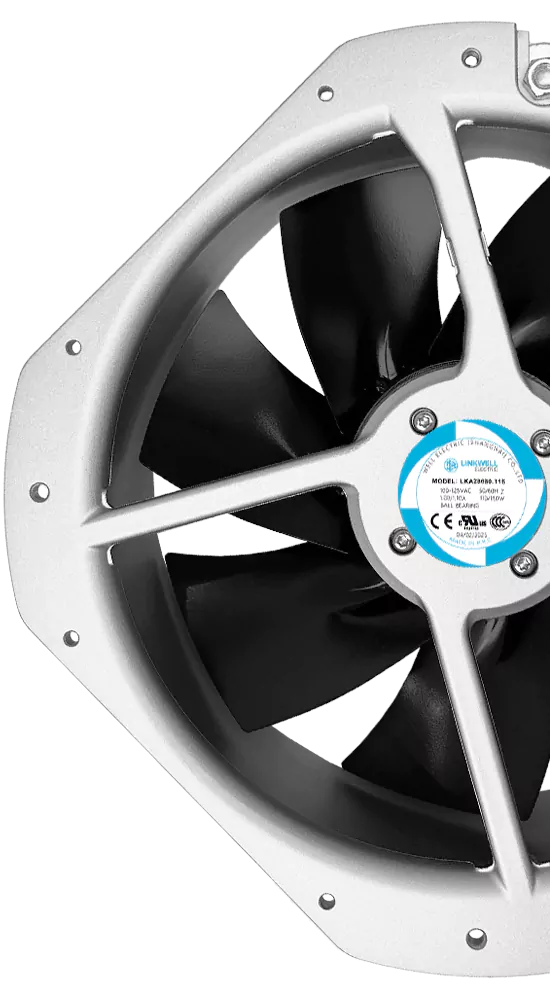

You have two main choices for industrial cooling: axial fans and centrifugal fans. Each type has its own strengths. Axial fans from fanacdc offer high airflow at low pressure. They use a compact design and are easy to maintain. Centrifugal fans deliver high-pressure airflow, making them perfect for systems with filters or ducts.

Here’s a quick comparison:

| Feature | Axial Fans | Centrifugal Fans |

|---|---|---|

| Airflow | High airflow at low pressure | High-pressure airflow |

| Design | Compact and simpler design | More complex and heavier design |

| Power Usage | Lower power consumption | Typically higher power consumption |

| Noise Levels | Generally noisier | Operate more quietly |

| Maintenance | Easier maintenance due to simple design | More maintenance required due to complex design |

| Applications | General cooling and ventilation | Specific directed cooling applications |

Axial fans work well in power generators, HVAC systems, and electronics cooling. Centrifugal fans shine in hot air exhaust, dust collection, and handling corrosive gases. Fanacdc gives you plenty of options, including custom sizes, voltage choices, and advanced engineering features. You can pick fans with IP protection, high-temperature resistance, and tailored airflow curves for your industrial needs.

Note: Fanacdc’s customizable solutions help you match the right fan to your application, so you get reliable cooling and maximum efficiency.

If you want to optimize your industrial cooling system, focus on correct fan sizing, airflow, and static pressure. Use the right fan type for your setup. Fanacdc’s engineering-driven products make it easy to get the best performance for every industrial scenario.

Enhancing Efficiency with Advanced Controls

Variable Frequency Drives and PWM

You want your industrial fan systems to run smarter, not harder. Variable frequency drive, or vfd, and pulse width modulation, or pwm, are two powerful optimization strategies. These technologies let you control fan speed and airflow with precision. When you use vfd and pwm, your fans draw only the energy needed for the current load. This means reduced energy consumption and lower electricity bills. You get enhanced performance and better cooling without wasting power.

- vfd and pwm allow you to fine-tune system performance, so you can match fan speed to demand.

- Fans operate only as fast as necessary, which leads to energy savings and less wear on mechanical parts.

- Controlled acceleration and deceleration protect your equipment and extend its life.

- Real-time adaptability means your industrial fan systems respond instantly to changing conditions.

| Fan Speed | Energy Consumption Reduction |

|---|---|

| 100% | 0% |

| 80% | ~50% |

| 70% | ~50% |

Advanced control systems, like PLCs and BMS, give you total control over airflow management and performance optimization. You can adjust settings on the fly, making sure your cooling stays efficient and reliable.

Placement and Installation Best Practices

Getting the most out of your industrial fan systems starts with strategic placement. You should install fans at a height that allows for proper airflow and optimal airflow distribution. In high-ceiling facilities, ceiling-mounted fans push hot air down, balancing temperature and boosting efficiency. Position fans to work with your HVAC system, so you get enhanced airflow design and cooling.

- Space fans evenly to avoid stagnant air and ensure consistent airflow distribution.

- Use fans to supplement natural airflow, drawing in cooler air and expelling hot air.

- Place fans near heat sources for performance optimization and better cooling.

- Position fans for safety, dispersing fumes and keeping work areas comfortable.

When you follow these optimization strategies, you maximize cooling and reduce energy consumption across your industrial setup.

Maintenance and Monitoring for Industrial Fan Systems

Regular maintenance keeps your industrial fan systems running at peak efficiency. You should set up a maintenance schedule and check key components like fan wheels, bearings, and motor drives. Use temperature and vibration sensors for continuous monitoring. This helps you spot issues early and avoid costly downtime.

- Install sensors to monitor vibration, temperature, and pressure.

- Use AI and data analytics to analyze performance data.

- Conduct root cause analysis when you detect anomalies.

- Develop a proactive maintenance plan based on predictive insights.

Predictive maintenance lets you schedule repairs only when needed, extending the life of your industrial fan systems. Real-time monitoring supports performance optimization and ensures proper airflow. Fanacdc supports advanced control and monitoring solutions, helping you achieve optimal airflow and enhanced performance in every industrial application.

Leveraging Technology and Custom Solutions

Simulation and Data-Driven Optimization

You can boost your industrial cooling system’s efficiency by using simulation and data-driven tools. Computational Fluid Dynamics (CFD) modeling helps you visualize airflow patterns and find the best equipment placement. You get to see how air moves, where hot spots form, and how to fix them before you even install a fan. CFD lets you test different scenarios, so you can optimize blast freezing, reduce energy use, and keep product quality high. You also improve defrost cycles and meet industry standards with fewer surprises.

| Benefit | Description |

|---|---|

| Optimized Airflow and Equipment Placement | CFD modeling determines ideal airflow patterns for uniform cooling and optimal equipment placement. |

| Scenario Simulation | Simulations of different conditions help optimize the blast freezing process. |

| Time and Energy Efficiency | CFD modeling reduces freezing time and energy consumption, enhancing operational efficiency. |

| Product Quality Preservation | Ensures consistent temperatures to maintain product quality and prevent ice crystal formation. |

| Defrost Cycle Efficiency | Optimizes defrost efficiency through simulations of airflow and heat transfer within the system. |

| Compliance and Quality Assurance | Aids in meeting industry standards and identifying potential issues for preventive maintenance. |

You can also use real-time monitoring to track airflow, noise, and vibration. Advanced control methods and smart sensors help you adjust fan speed and energy use instantly. This keeps your cooling system running smoothly and saves money.

Custom OEM/ODM AC Fans by fanacdc

Sometimes, you need a fan that fits your exact requirements. Fanacdc offers custom OEM and ODM AC fans for industrial applications. You get durability, efficiency, and flexibility. Choose from different voltages, blade sizes, and motor speeds. These fans come with certifications like CE, UL, and RoHS, so you know they meet safety standards. Fanacdc’s custom solutions work in energy storage, telecommunications, renewable energy, and automation. You get reliable cooling and strong airflow, even in tough environments.

| Benefit/Feature | Description |

|---|---|

| Durability | Rugged build for industrial use. |

| Efficiency | High efficiency for optimal performance. |

| Flexibility | Voltages from 110V to 380V, blade diameters from 80mm to 280mm. |

| Customization | OEM, ODM, and OBM services for tailored solutions. |

| Certification | CE, UL, RoHS, and T-v certifications. |

| CFM Output | 16.5 to 1150 CFM for different cooling needs. |

| Motor Speed | 1800 to 3200 RPM depending on the model. |

| Reliability | Dependable performance in high-demand environments. |

Avoiding Common Mistakes in Industrial Fan Systems

You want your cooling system to run at peak efficiency. Avoid these common mistakes:

- Pick the right fan type and size using airflow curves and system resistance calculations.

- Design ductwork for smooth airflow and low resistance.

- Clean and inspect impellers often.

- Use predictive maintenance for bearings and shaft alignment.

- Install Variable Frequency Drives for energy-efficient control.

- Choose materials that resist corrosion in harsh environments.

- Balance fans and monitor vibration.

- Focus on reliability-centered maintenance.

- Correct for air density and temperature when sizing fans.

- Follow AMCA guidelines for installation and ductwork.

Tip: Smart technologies, IoT, and advanced blade designs are changing the way you manage industrial cooling. Custom solutions from fanacdc help you meet new energy standards and keep your systems running strong.

Conclusion

You now have a clear path to get the most out of your industrial AC cooling fans. Start by mapping out your facility’s heat zones and measuring any obstacles. Pick the right fan type for each area—large HVLS fans for open spaces, axial fans for doorways, and blowers for ducts. Always check that your fans cover the right range and connect them to a smart control system for easy adjustments.

Here are some key takeaways from recent research and case studies:

- Advanced motors that work well at lower speeds help you save energy.

- Motors with flat efficiency curves keep your system running strong in different conditions.

- Choosing the right motor size for your application cuts down on wasted energy.

- Fan cooling can boost comfort and save up to 25% more energy than traditional HVAC systems.

- Air temperature and speed matter—a setting of 29°C with airflow at 0.4 m/s works best for many setups.

You can also follow these simple steps to keep your system running smoothly:

- Monitor and adjust thermostat settings, or use a programmable thermostat.

- Manage airflow to improve cooling performance.

- Check refrigerant levels often.

- Inspect electrical connections for safety.

- Upgrade to energy-efficient models when possible.

Tip: Regular maintenance and smart controls make a big difference in system reliability and energy savings.

If you want a reliable, high-performance solution, fanacdc offers customizable fans and expert support for every industrial need. Create a quick-reference checklist for your team, and you’ll keep your cooling system efficient all year long.

You can get the most from your industrial AC cooling fans by picking the right fan, using advanced controls, and taking advantage of new technology. When you size your fans precisely and use smart controls, you boost energy efficiency and help your equipment last longer. For ongoing success, keep this checklist handy:

- Know your equipment’s cooling needs.

- Install servers for the best airflow.

- Keep aisles and cabinets clear.

- Use blanking and side panels.

- Set temperature alarms.

- Work with your cooling provider.

Fanacdc gives you reliable, customizable solutions to keep your system running strong.

FAQ

What’s the difference between an AC fan and a DC fan?

You get steady airflow and easy installation with AC fans. DC fans give you precise speed control and better energy savings. Choose AC for simple, robust cooling. Go with DC if you want more control and lower power bills.

How do I know what size fan I need?

Start by checking your equipment’s heat output. Look at your available space. Use airflow and static pressure charts. If you’re unsure, ask fanacdc for help. They’ll match you with the right size for your setup.

Can I control the speed of my AC cooling fan?

Yes, you can! Use a variable frequency drive (VFD) or a voltage regulator. These let you adjust fan speed to match your cooling needs. You save energy and reduce noise.

When should I consider a custom fan solution?

You should think about custom fans when you have unique voltage, size, or airflow needs. Custom solutions from fanacdc fit special cabinets, harsh environments, or strict noise limits. You get exactly what your project requires.