If you’ve ever wondered about the types of fans and what they actually do, you’re not alone. Fans play a huge role in keeping spaces comfortable and safe, whether you’re at home, work, or in an industrial setting. Here are some common types of fans you’ll see every day:

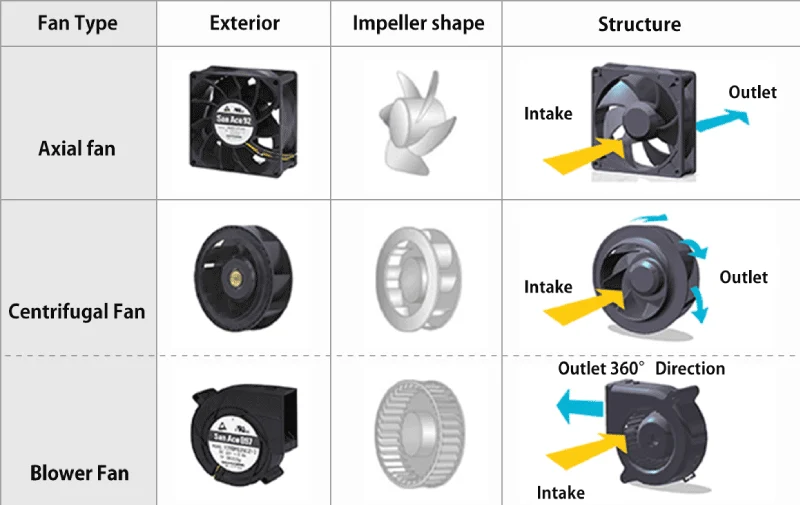

- Axial fans move air straight through to cool rooms or machines.

- Centrifugal fans draw air in and push it out at a 90-degree angle, perfect for high-pressure needs.

- Exhaust fans remove stale air from kitchens, bathrooms, and laundry rooms.

- Supply fans bring in fresh air to offices and factories.

- Ceiling fans circulate air for comfort.

- Whole house fans ventilate your entire home.

Choosing the right fan can boost efficiency and help you save energy—some energy-efficient fans even cut power usage by up to 70%. You get better comfort, lower costs, and a healthier environment just by picking the right fan for your space.

Key Takeaways

- Identify the right fan type for your needs: Axial fans cool spaces, centrifugal fans handle high pressure, and exhaust fans remove stale air.

- Choose energy-efficient fans to save money: Some models can reduce power usage by up to 70%, lowering your energy bills.

- Consider room size when selecting a fan: Match the fan diameter to your room’s square footage for optimal airflow and comfort.

- Regular maintenance extends fan life: Clean blades, check for damage, and lubricate motors to keep fans running smoothly.

- Understand fan applications: Residential fans suit homes, commercial fans fit offices, and industrial fans work in tough environments.

Types of Fans Overview

When you start looking at the different types of fans, you’ll notice three main categories: residential, commercial, and industrial. Each one serves a unique purpose and fits specific environments. Here’s a quick comparison to help you see how they differ:

| Fan Type | Design Features | Application Characteristics |

|---|---|---|

| Residential | Designed for intermittent use, smaller spaces, lower airflow capacities | Used in homes for cooling and comfort |

| Commercial | Built for moderate use, larger than residential fans, higher airflow | Used in offices, retail spaces for ventilation |

| Industrial | Robust, continuous operation, larger propellers, durable materials | Used in harsh environments, high airflow requirements |

Residential Fans

You probably use residential fans every day. These common fan types include desk fans, pedestal fans, tower fans, wall-mounted fans, and ceiling fans. They’re made for smaller spaces and designed to keep you comfortable at home. You’ll find options in different styles and materials, so you can pick one that matches your room. Residential fans work best for cooling bedrooms, living rooms, or home offices. They’re easy to install and move around.

Tip: If you want to improve comfort in your home, try using a ceiling fan or a portable air circulator. These fans help with ventilation and keep air moving.

Commercial Fans

Commercial fans step up the game. You’ll see them in offices, stores, and restaurants. They’re bigger than residential fans and push more air to handle larger spaces. These fans help with ventilation and keep indoor air fresh for customers and employees. You might notice them in HVAC systems or as supply and exhaust fans in commercial buildings. They’re built for moderate use and offer higher airflow than home fans.

Industrial Fans

Industrial fans are the heavy-duty champions. You’ll find them in factories, warehouses, and power plants. These fans run nonstop, move huge volumes of air, and handle tough conditions. Industrial fans play a key role in ventilation, HVAC, cooling, exhaust systems, material handling, and even air pollution control. They’re built with durable materials and advanced technology to meet strict standards for safety and efficiency.

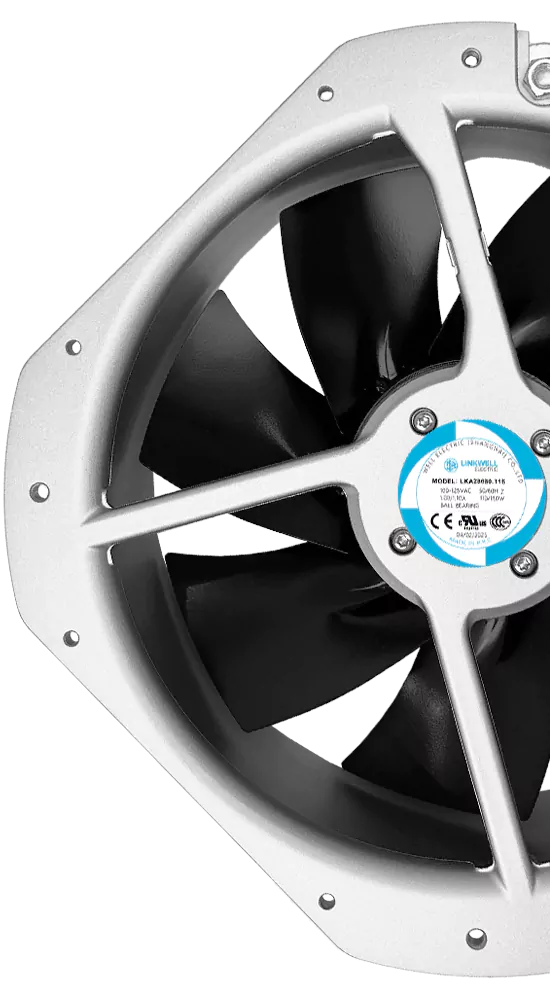

Fanacdc stands out in the world of industrial cooling solutions. With decades of experience, fanacdc designs and manufactures high-performance industrial fans for demanding environments. If you need reliable ventilation, HVAC, or cooling in your industrial space, fanacdc offers products that deliver efficiency and durability.

Understanding the types of fans helps you pick the right solution for your needs. The right fan improves efficiency, saves energy, and creates a healthier environment. When you know what each fan does, you can optimize ventilation, control airflow, and boost indoor air quality.

Industrial Fan Solutions by fanacdc

When you step into an industrial setting, you need cooling fans that can handle tough jobs and keep your equipment running smoothly. fanacdc offers a complete lineup of fans designed for every industrial challenge. Whether you need to move high airflow through a factory, control temperature in a server room, or manage exhaust in a processing plant, you’ll find a solution that fits.

Here’s a quick look at how fanacdc’s product range matches different industrial needs:

| Product Type | Key Features | Applications |

|---|---|---|

| AC Fans | Long-term durability, engineered for over 50,000 hours of operation | Industrial and commercial applications |

| DC Fans | Operate at speeds up to 8,000 RPM, highly efficient, stable cooling | Various industrial settings |

| EC Fans | Energy-efficient, consume up to 75% less power, low power usage of 2W | Cost-sensitive applications |

| Centrifugal Fans | Generate static pressure up to 300 Pa, high airflow efficiency | Compact systems |

Let’s break down what makes each type of fan special and how you can use them to improve your airflow, cooling, and exhaust systems.

Centrifugal Fan

If you need a fan that delivers high airflow and strong pressure, centrifugal fans are your go-to choice. These fans pull air in and push it out at a 90-degree angle, which is perfect for moving air through long ducts or filters. You’ll see them in HVAC systems, dust collection, and even in chemical processing where reliable airflow is a must.

Some unique features of centrifugal fans from fanacdc include:

- They generate high, reliable pressure, making them ideal for demanding industrial applications.

- You can use them in HVAC systems to move conditioned air through extensive ductwork and filters.

- They work well in dust collection systems, material conveying, and specialized ventilation for chemical processing.

You can choose from different types of centrifugal fans, depending on your needs:

- Forward-curved fans give you high airflow at low pressure, great for HVAC.

- Backward-curved fans offer higher efficiency and pressure with lower noise, perfect for industrial use.

- Radial-blade fans handle dust-laden gases and are easy to clean, making them rugged for tough jobs.

fanacdc’s centrifugal fans meet strict standards for quality and safety. Here’s a quick look at their certifications:

| Certification Type | Description |

|---|---|

| ISO9001 | Quality Management System |

| IS014001 | Environmental Management System |

| UL Certification | Safety for AC fans and DC axial fans |

| EMC Certificate | Electromagnetic Compatibility for AC fans |

| LVD Certificate | Low Voltage Directive for AC fans |

| CE Certificate | Compliance for DC fans |

| RoHS | Restriction of Hazardous Substances for AC and DC fans |

You can count on these fans for durability and long service life, even in harsh environments.

Industrial Cooling Fan

Industrial cooling fans from fanacdc are built to keep your equipment safe and your workspace comfortable. You’ll find them in manufacturing plants, food and beverage processing, and even in pharmaceutical cleanrooms. These fans prevent overheating, control temperature, and help maintain air quality.

Here’s what you get with fanacdc industrial cooling fans:

- They create cooler and safer work environments by improving air quality and temperature.

- They handle high temperatures and continuous operation with ease.

- They meet large-scale airflow requirements, making them perfect for big spaces.

- They help release hazardous gases and toxins, keeping your staff safe.

- They dry materials quickly, boosting productivity.

- They protect your equipment from overheating and extend its life.

You can rely on these cooling fans to deliver stable airflow and keep your operations running smoothly. They also help you save energy by optimizing operational temperatures.

AC Fans

AC fans are the workhorses of industrial cooling. If you want a fan that lasts a long time and needs little maintenance, AC fans are a solid pick. They provide stable airflow and can handle heavy-duty applications like electrical enclosures, automation systems, renewable energy equipment, and telecom cabinets.

Check out some of the top advantages of fanacdc AC fans:

| Characteristic/Advantage | Description |

|---|---|

| Durability | AC fans are built to last, with a lifespan of 50,000 to 60,000 hours under normal conditions. |

| Stable Airflow | They provide consistent airflow, essential for continuous operation in industrial settings. |

| Low Maintenance | AC fans require minimal maintenance, typically only needing bearing replacements over time. |

| Cost-Effectiveness | They offer strong performance at a lower initial cost compared to DC and EC fans. |

| High Static Pressure | AC fans can handle higher voltage and generate stronger static pressure, suitable for heavy-duty applications. |

You can customize AC fans to fit your exact needs. fanacdc offers options for size, mounting, voltage, and speed curves. You can also get enhanced protection for adverse environments, like IP-rated designs and corrosion-resistant materials. If you need a quick solution, fanacdc provides rapid prototyping and short lead times.

DC Fan

When you need quiet, energy-efficient cooling, DC fans are a smart choice. These fans use brushless motors, which means they run smoothly and quietly. You’ll often see DC fans in places where you need precise airflow control, like electronics, automation, and sensitive industrial equipment.

Here’s what sets fanacdc DC fans apart:

| Feature/Advantage | Description |

|---|---|

| Lower Power Consumption | DC fans use up to 70% less power than AC fans, leading to reduced electricity bills. |

| Minimal EMI | They produce minimal electromagnetic interference, making them ideal for sensitive environments. |

| Lower Noise | DC fans operate more quietly due to smoother operation and lower speeds. |

| Lower Voltage | Typically operate at 12V or 24V, facilitating easier integration into various systems. |

| Waterproof | Their sealed construction protects against moisture exposure. |

| More Speed Options | Offer a wider range of speed settings, typically 3 to 7 or more. |

| Variable Flow | Provide stepless speed control for optimal airflow and energy efficiency. |

| More Compact Design | Smaller and lighter, making them suitable for confined spaces without compromising performance. |

You’ll notice that DC fans are generally quieter than AC fans because of their brushless motor design and optimized blade geometry. They also help you save energy, especially in variable-load environments, and can achieve up to 70% energy savings compared to fixed-speed AC fans.

If you’re looking for a fan that fits into tight spaces, offers variable airflow, and keeps noise to a minimum, DC fans from fanacdc are a great fit.

Tip: For applications that need both high airflow and pressure, consider mixed-flow fans. They combine the best features of axial fans and centrifugal fans, giving you flexibility for unique industrial setups.

No matter what your industrial needs are, fanacdc has a cooling fan solution that delivers reliable airflow, efficient cooling, and dependable exhaust performance. You can trust their products to meet strict certifications and offer customization for any environment, from compact systems to large-scale exhaust systems.

How to Choose the Right Fan Type

Choosing the right fan can make a big difference in your comfort, energy bills, and the overall efficiency of your space. You want to match the types of fans to your needs, whether you’re cooling a bedroom, ventilating a warehouse, or keeping equipment safe in an industrial setting. Let’s break down what you should look for.

Room Size and Placement

Start by measuring your room. The size of your space helps you pick the right fan diameter. Here’s a quick guide:

- Measure the length and width of your room in feet.

- Match your room size to fan diameter:

- Up to 75 sq ft: 29–36 inches

- 76–144 sq ft: 36–42 inches

- 144–225 sq ft: 44–50 inches

- 225–400 sq ft: 50–54 inches

- Over 400 sq ft: 60 inches or larger

- Keep fan blades at least 7 feet above the floor. For ceilings taller than 9 feet, use a downrod.

Strategic placement boosts air circulation. Put fans near windows or doors to draw in fresh air and push out hot air. In large rooms, you may need more than one fan to avoid drafts and keep temperatures even.

Energy Efficiency

Energy-efficient fans help you save money and reduce your carbon footprint. Look for ENERGY STAR-certified models, which use up to 60% less energy than traditional units. Here’s a quick comparison:

| Fan Type | Power Consumption (Watts) | Annual Operating Cost | Lifespan (Years) | Energy Savings (%) |

|---|---|---|---|---|

| Energy Saver Fan | 25-35 | $10 | 10-15 | Up to 60% |

| Traditional Fan | 70-80 | $30 | 5-10 | N/A |

If you want even more efficiency, consider EC fans from fanacdc. These fans use advanced motor technology to cut power usage by up to 75%, making them perfect for hvac and industrial ventilation systems.

Application Needs

Think about what you need your fan to do. Are you looking for cooling, ventilation, or air purification? Here’s what matters:

- Air movement (CFM): Make sure the fan moves enough air for your space.

- Static pressure: Important for hvac systems with long ducts or filters.

- Noise level: Pick quieter fans for offices or bedrooms.

- Size and form factor: Make sure the fan fits your space.

- Power supply: Check voltage and connector type.

- Durability: Choose fans with long lifespans for industrial ventilation.

| Fan Type | Application | Impact on Efficiency and Comfort |

|---|---|---|

| Industrial Centrifugal Fan | Material handling and dust collection | Ensures reliable airflow essential for operations |

| Rotating Blowers | hvac systems | Maintains high performance under varying load conditions |

If you need help matching fan features to your application, fanacdc offers customization and technical support. Their team can help you pick the right fan for your hvac, industrial, or commercial project.

Installation and Maintenance

Proper installation keeps your fans running smoothly. Make sure you follow these steps:

- Clean fan blades regularly to prevent dust buildup.

- Inspect for damage and replace faulty parts.

- Monitor airflow and noise for any changes.

- Lubricate motors and bearings as needed.

- Check electrical connections for corrosion.

fanacdc supports you with startup assistance, ongoing maintenance, vibration analysis, and training. Their experts help you install fans correctly and keep them working efficiently for years.

Tip: Regular maintenance not only extends the life of your fans but also keeps your hvac and industrial ventilation systems running at peak efficiency.

Conclusion

You’ve learned a lot about the types of fans and how each one can make a difference in your space. Whether you’re cooling a bedroom, ventilating a warehouse, or keeping machines safe, picking the right fan matters. Let’s recap the main benefits you get from using fans in different environments:

- Thermal comfort: Fans help you feel cooler by moving air and speeding up heat loss.

- Energy savings: Using fans can cut down on air conditioning, which lowers your energy bills.

- Cost reductions: Fans often cost less to buy and run, especially in large spaces.

- Improved air distribution: Fans work with HVAC systems to keep temperatures and air quality steady.

- Better indoor air quality: Fans help clear out pollutants and keep the air fresh.

Here’s a quick look at how different types of fans fit into various applications:

| Fan Type | Key Characteristics | Applications |

|---|---|---|

| Axial | Space-saving designs | General cooling |

| Centrifugal | High-pressure capabilities | Industrial applications |

| Blowers | Direct airflow, high velocity | Ventilation systems |

| Cross Flow | Uniform airflow distribution | Air conditioning systems |

| Miniature | Compact size | Electronics cooling |

If you want to make sure you choose a reliable and efficient fan, keep these tips in mind:

- Airflow comes first. For industrial use, look for at least 80 CFM.

- Noise control matters. Pick fans with lower dB levels for quieter operation.

- Size compatibility is key. Make sure the fan fits your space, leaving a little room for installation.

- Special environments need special features. Check for IP ratings if you’re installing fans outdoors or in chemical areas.

- Smart upgrades help. Four-pin PWM fans adjust speed based on temperature, boosting efficiency.

Remember: Efficiency isn’t just about saving energy. It’s about getting the best performance, comfort, and reliability for your needs. When you choose fans from trusted brands like fanacdc, you get advanced technology, strong support, and products built to last.

If you’re ready to upgrade your ventilation or cooling system, take a moment to review your space, your needs, and the features that matter most. The right fan will help you stay comfortable, save money, and keep your equipment running smoothly.

You now know how different fans work and why picking the right one matters for your space. When you choose a fan, keep these tips in mind:

- Check airflow and static pressure for strong air movement.

- Look for quiet operation if you need a peaceful environment.

- Match the size and materials to your space.

- Think about heat and humidity where you install the fan.

- Review performance curves to find the best fit.

A reliable brand with solid features will help you feel confident in your choice.

FAQ

What’s the difference between axial and centrifugal fans?

Axial fans move air straight through the blades. Centrifugal fans pull air in and push it out at a right angle. You’ll see axial fans in homes and centrifugal fans in industrial spaces.

How do I know which fan size is right for my room?

Measure your room’s length and width. Match the square footage to the recommended fan diameter. Bigger rooms need larger fans for better airflow and comfort.

Can I use industrial fans at home?

Industrial fans work best in large, open areas. They’re powerful and can be noisy. For your home, stick with residential fans designed for quiet and comfort.

How often should I clean my fan?

Clean your fan every few months. Dust can build up and slow down airflow. Wipe the blades and check for any loose parts to keep everything running smoothly.

Are energy-efficient fans worth it?

Yes! Energy-efficient fans use less electricity. You’ll save money on your bills and help the environment. Look for models with ENERGY STAR ratings or advanced motor technology.