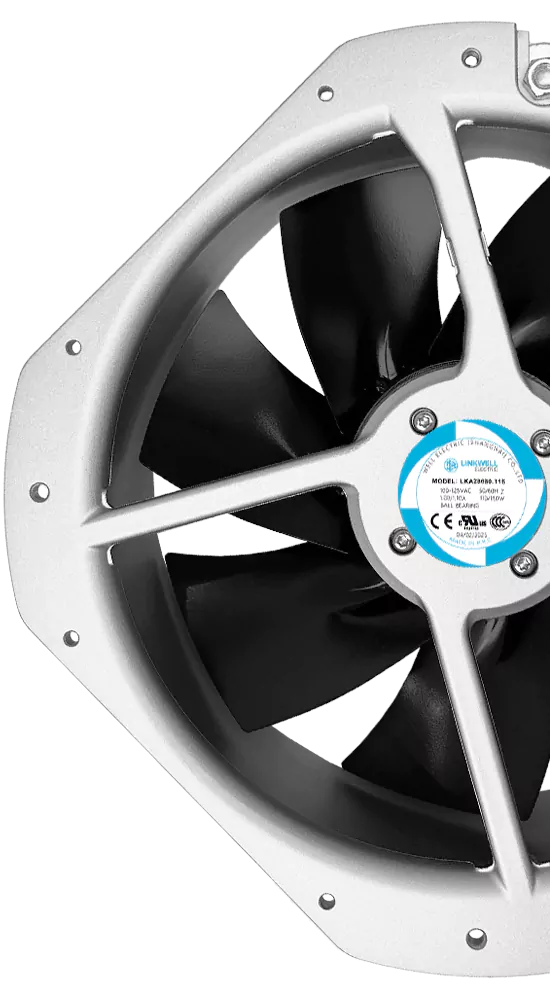

Engineered for stable airflow, high static pressure, and long-lasting reliability

133-355 mm

Size Range

115-240 V

Voltage

159-1735 CFM

Air Volume

60,000 hour

Service Life

Fan

Model

Size

(mm)

Voltage

(VAC)

Power

(W)

Speed

(RPM)

Airflow

(CFM)

Brushless and shaded-pole motor options deliver optimized efficiency and reduced energy loss.

Precisely engineered blades ensure balanced airflow and low vibration for continuous operation.

Flame-retardant housings and sealed bearings guarantee longevity even in harsh industrial conditions.

Backed by multiple patents, our fans meet ISO, CE, UL, and RoHS standards for safety and performance.

Centrifugal fans operate by using a rotating impeller to draw air into the center and accelerate it outward through centrifugal force. This process converts rotational energy into high-pressure airflow, making them ideal for systems that require stable air volume against resistance.

Compared to axial fans, centrifugal models provide higher static pressure, precise airflow direction, and improved efficiency in confined or ducted environments — making them the preferred choice for HVAC, industrial automation, air filtration, and purification systems.

Centrifugal fans ensure efficient air movement and filtration in ventilation, air conditioning, and air handling units, maintaining stable airflow for comfortable and clean environments.

Deliver stable airflow to condensers, evaporators, and cooling coils, supporting consistent temperature control in supermarkets, cold storage, and food processing facilities.

Offer dependable heat dissipation for UPS, inverters, and energy storage systems, improving efficiency and extending the service life of critical power equipment.

Our centrifugal fans can be customized across dimensions, impeller design, and performance curves to perfectly match your system requirements. Whether you need compact housings, higher airflow, or specific static pressure, our engineering team ensures precise compatibility and smooth integration.

Each solution is optimized for efficiency, stability, and durability to meet industrial-grade expectations and enhance overall equipment performance.

For demanding environments, we offer enhanced protection through IP-rated designs, salt-spray resistance, and high-temperature operation. These upgrades guarantee reliable performance in harsh industrial, coastal, or outdoor conditions.

By combining corrosion-resistant materials and precision sealing technology, our centrifugal fans maintain consistent airflow and extended service life even under continuous stress or exposure.

We provide full engineering support from concept to production, allowing you to customize airflow performance, housing shape, and motor configuration. Our rapid prototyping service turns design ideas into functional samples within days, enabling quick testing and validation.

By combining precision engineering and agile manufacturing, we deliver tailored centrifugal fan solutions that meet exact specifications with reduced development time.

A centrifugal fan is a high-efficiency mechanical device designed to move air or other gases. Often referred to as “blowers” or “squirrel cage fans,” their defining feature is changing the airflow direction by 90 degrees.

Air enters the fan’s inlet axially (parallel to the rotating shaft) and is drawn into the center of the impeller. The impeller, which consists of a series of blades, then accelerates the air outwards radially using centrifugal force. This high-velocity air is collected by a spiral-shaped housing (casing or volute), which slows the air down, converting its kinetic energy into static pressure.

This ability to build high pressure—often measured in inches of water gauge (WG) or Pascals—makes them distinct from axial fans. They are the preferred choice for systems with high resistance, such as long ductwork, filter banks, or industrial processes that require a concentrated, high-pressure airstream.

A centrifugal fan operates on the principle of centrifugal force.

The process begins when air enters the fan housing through the inlet, moving parallel to the fan’s shaft (axially). This air is guided directly into the “eye” (the center) of the rotating impeller. As the impeller spins, its blades catch the air and accelerate it, slinging it outwards in a radial direction (at a 90-degree angle from the inlet).

This acceleration imparts significant kinetic energy (velocity) to the air. The fast-moving air then exits the impeller tips and enters the fan’s casing, which is typically spiral-shaped (a “volute”). The volute is designed to gradually expand, which slows the air down. According to Bernoulli’s principle, as the air’s velocity decreases, its kinetic energy is converted into potential energy in the form of static pressure.

This high-pressure air is then channeled to the fan’s single outlet, ready to overcome resistance.

Selecting the right centrifugal fan is critical for system performance, energy efficiency, and operational lifespan. The process requires several key data points.

First, you must define the airflow rate (Volume), typically measured in Cubic Feet per Minute (CFM) or cubic meters per hour (m³/h).

Second, determine the static pressure (Pressure) required. This is the total resistance the fan must overcome, measured in Pascals (Pa) or inches of water gauge (in. WG), and includes friction losses from ducts, filters, and dampers.

Third, identify the air properties: Is the air hot, corrosive, or carrying abrasive particles (e.g., sawdust or metal fines)? This will dictate the fan’s construction materials and blade type. For example, a radial blade fan is excellent for material handling, while a backward-inclined fan offers high efficiency for clean air.

Finally, consider noise levels (dBa) and available space. Using a fan curve chart is essential to match these requirements to a specific fan model that operates at or near its Best Efficiency Point (BEP).

Centrifugal fans are used across a vast range of commercial and industrial applications, primarily chosen for their ability to generate high, reliable pressure.

In HVAC systems, they are the workhorses for moving conditioned air through extensive ductwork, filters, and heating/cooling coils in office buildings, hospitals, and data centers.

In industrial processes, their applications are even more diverse. They are essential for dust collection systems (e.g., in woodworking or metal fabrication shops), providing the high suction needed to capture fine particles. In material conveying (e.g., plastic pellets or grain), radial-bladed fans can move the material directly.

Other common uses include specialized ventilation for chemical processing (using corrosion-resistant materials like FRP), fume exhaust in laboratories. Even small “blowers” in electronics are centrifugal fans, forcing cool air over hot components.

The main difference lies in the airflow direction and pressure generation.

Axial fans move air parallel to the fan shaft, similar to how a propeller works, providing high airflow with low pressure — best for open spaces or cooling systems with minimal resistance.

Centrifugal fans, on the other hand, move air perpendicular to the shaft, producing higher static pressure and stable flow — ideal for ducted or filtration systems.

Axial fans are generally more compact and energy-efficient for low-pressure needs, while centrifugal fans handle heavier air resistance and deliver consistent performance in demanding environments. The choice between them depends on whether the application prioritizes volume (axial) or pressure (centrifugal).

Centrifugal fans are classified primarily by blade design, which affects performance and efficiency. The three main types are:

Forward-curved fans: Have many small blades curved in the direction of rotation. They provide high airflow at low pressure, suitable for HVAC or light-duty ventilation.

Backward-curved fans: Blades curve opposite to the direction of rotation, offering higher efficiency and pressure, with lower noise and energy consumption—common in industrial applications.

Radial-blade fans: Blades extend straight out from the center, ideal for handling dust-laden or abrasive gases due to their rugged design and easy cleaning.

Each type offers unique advantages depending on system resistance, air quality, and operating environment.

Speed control allows precise airflow regulation and improved energy efficiency. For AC centrifugal fans, speed is typically managed using a variable frequency drive (VFD), which adjusts the motor’s input frequency and voltage. VFDs enable smooth speed transitions, reduce mechanical stress, and cut energy costs during partial-load operation.

In simpler setups, dampers can restrict airflow, but they waste energy compared to electronic control. Modern systems favor variable-speed drives for better efficiency, noise reduction, and adaptability to dynamic ventilation demands, ensuring the fan delivers only the airflow required by the system.

WhatsApp us

Curious how LINKWELL’s cooling solutions can address your business challenges? Let’s connect and discuss your needs.